Engine Development Division

Industrial Power Products Management Division

Power Solution Business

YANMAR Technical Review

3TNV80FT Industrial Engine: Achieving World-Leading Torque Performance for a 1L Diesel Engine

Abstract

Strict emission regulations in recent years have led to greater demand for engines in the sub-19 kW class, a response to the higher cost of larger-sized engines. This in turn has created a need for better torque performance and for sub-19 kW engines to satisfy requirements for a variety of applications.

The 3TNV80FT was developed to be a sub-19 kW engine that is both compact and provides a high level of torque performance.

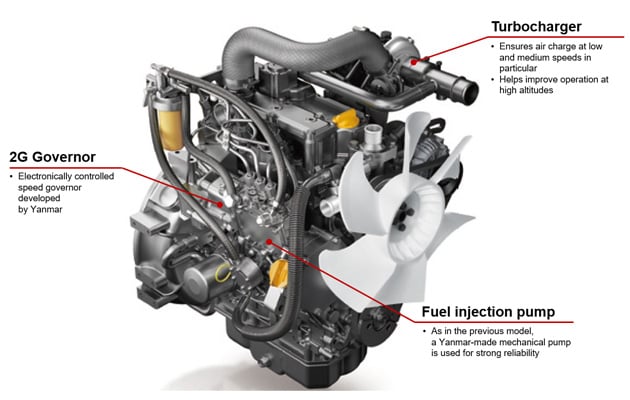

The combination of high torque performance and clean emissions was achieved through use of turbocharging together with the 2G Eco Governor. Developed in-house by Yanmar, the 2G Eco Governor is an electronically controlled speed governor that provides a high degree of freedom in the control of the fuel injection amount.

These features also help the engine maintain performance under different environmental conditions while satisfying the requirements of different applications.

This report describes the technologies used in the 3TNV80FT engine.

1. Introduction

Yanmar's sub-19 kW small diesel engines have earned a good reputation in the market for using mechanical fuel injection to comply with the latest emission regulations, including the Final Tier 4 regulations in the USA and the Stage V regulations in Europe.

Stricter emission regulations in recent years have meant that engines above 19 kW of output need to be fitted with common rail systems, diesel particulate filters (DPFs), or other costly emission control measures, and this has led to stronger demand for engines below 19 kW, which are less expensive by comparison. Along with the regulatory changes, Yanmar has also seen demand for engines of just under 19 kW as replacements for engines in the 20 kW range. The requirement in this case is to provide high levels of torque performance despite the engine being in the sub-19 kW class.

Engines in the sub-19 kW class serve a diverse range of market needs, being widely used in machinery used by ordinary households, such as lawnmowers, as well as in construction machinery and other commercial applications.

This report describes the technologies and features of the 3TNV80FT engine that went on sale in 2016 and was developed on the basis of these market needs.

2. Product Overview

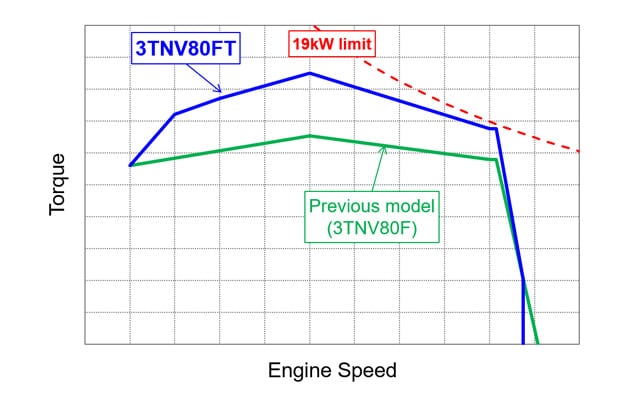

The 3TNV80FT was developed to meet the market demand for a compact diesel engine with class-leading torque performance in the sub-19 kW range. Fig. 2 shows the torque curve for the new model alongside that of the previous Yanmar engine in this category. By increasing torque at medium and low speed while also improving the rated torque as far as possible while remaining just under 19 kW, the new engine is able to deliver high torque across a wide speed range. Compliance with the US Final Tier 4 regulations was among the development targets for the engine, and it has also recently acquired certification for compliance with the European Stage V regulations. The result is a clean engine that is both powerful and considerate of the environment.

While these latest regulations also require that engines satisfy their emissions requirements when operating at high altitude (where air pressure is low), an issue with the previous model, which used a mechanical governor, was that it suffered excessively from performance degradation because it was unable to reduce the fuel injection amount (which has a direct bearing exhaust emissions) based on altitude in a linear manner. This problem has been dealt with in the new model by adopting the Yanmar 2G Eco-Governor, an electronically controlled governor developed in-house that varies the torque performance of the engine according to the altitude, thereby keeping the loss of output at high altitude to a minimum.

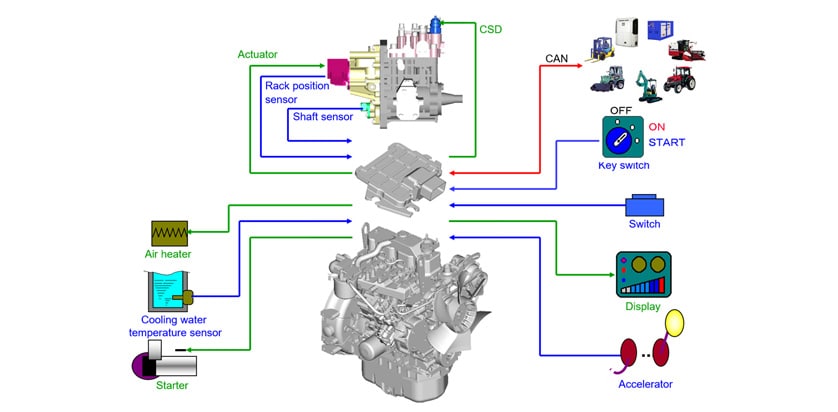

Another benefit of using an electronic governor is that it can use CAN communication to connect to the machine in which the engine is installed. This offers the potential to achieve high levels of energy efficiency through integration with the host machine's control systems.

3. Technologies and Features

3.1. High Torque Rise Due to 2G Eco-Governor and Turbocharging

To achieve the excellent torque performance (torque rise) that is its major feature, the new engine uses a turbocharger together with the 2G Eco-Governor that provides a high degree of control freedom in the amount of fuel injected.

Because keeping the engine power below 19 kW was a key requirement, it was necessary to increase the amount of fuel injected at low and medium speeds while still limiting the injection amount when operating at rated speed so as to remain just under 19 kW. Because this ability to adjust the fuel injection amount across different speeds was beyond the capabilities of the mechanical governor used on the previous model, it was achieved by instead fitting the 2G Eco-Governor. This new governor provides a high degree of control freedom in the amount of fuel injected.

Next, because increasing the fuel injection amount while leaving the amount of air unchanged is likely to result in higher PM emissions, a turbocharger was added to ensure sufficient air to match the increase in the amount of fuel injected at low and medium speeds. Fig. 4 shows the performance trade-offs that need to be considered when selecting the turbocharger. A number of prototypes with different specifications were built and tested in order to identify the optimal choice (see Fig. 5).

Together, these measures enabled the new engine to achieve both improved emissions performance and high torque rise.

3.2. Improvements to Operational Performance at High Altitudes

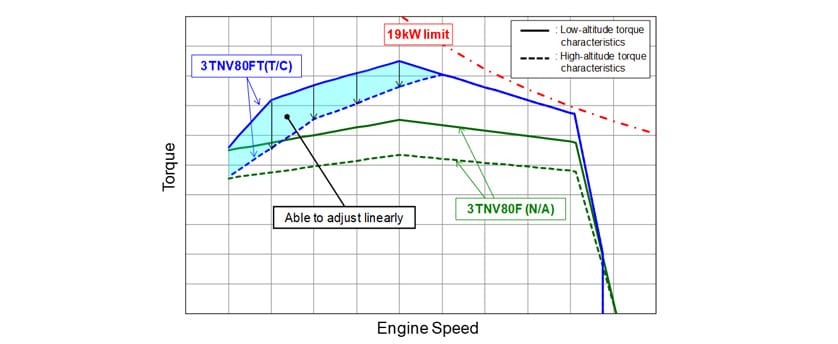

A problem when operating at high altitudes (where the air pressure and density are lower) is that the concentration of exhaust (Sd) can worsen due to incomplete combustion of the fuel. While this is typically dealt with by limiting the amount of fuel injected when operating at low atmospheric pressure, doing so degrades operational performance by reducing torque. The only way of dealing with this with the conventional mechanical governor was by switching between two different torque curves for normal and low air pressure conditions respectively, which meant that operational performance was degraded by more than necessary under some conditions. The new model, in contrast, uses the 2G Eco-Governor, which provides the ability to adjust the fuel injection amount across all speeds and also to use feedback from an atmospheric pressure sensor to change the amount linearly based on the altitude (see Fig. 6). The addition of a turbocharger also means the engine is better able than the previous model to obtain the required amount of air, eliminating the need to limit the amount of injected fuel at high speed even when operating at low atmospheric pressure.

This means that the new engine is better than the previous model at maintaining high operational performance, even when operating at low atmospheric pressure.

3.3. Product Enhancements Made Possible by Electronic Control

The new engine has been enhanced in the following ways by the adoption of the 2G Eco-Governor.

3.3.1. Use of Droop Control to Improve Operational Performance

A characteristic of the mechanical governor used in the past was that the engine speed would drop (droop speed control) as the engine went from no load to full load, with this speed drop being greater at low speeds (see Fig. 7). The adoption of the 2G Eco-Governor, in contrast, has improved the operational performance of the engine by keeping this speed drop roughly constant across the entire speed range. Moreover, by providing the optimal governor characteristics for the machine in which it is used, the new engine has also been equipped with an optional function for keeping the speed drop to zero (isochronous speed control).

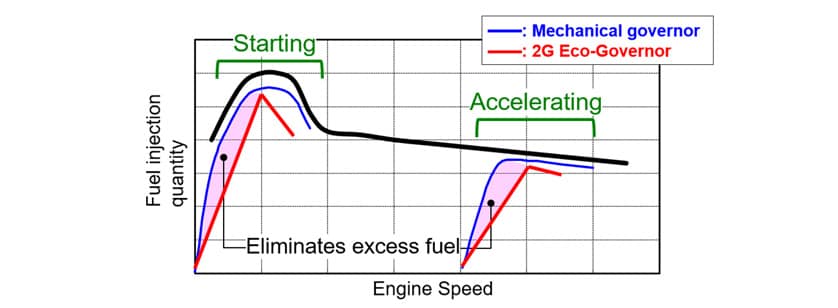

3.3.2. Improvements in Fuel Consumption by Eliminating Excess Fuel Injection when Starting or Accelerating

As the mechanism in the mechanical governor for adjusting how much fuel to inject is controlled by a spring, excessive fuel is injected during transient conditions such as when starting or accelerating, resulting in black smoke emissions and deterioration in terms of fuel consumption. The 2G Eco-Governor, in contrast, can avoid black smoke and improve fuel consumption because it uses a linear solenoid to adjust the injection amount, allowing it to maintain an appropriate fuel injection amount even during transient conditions.

3.3.3. Potential for Control System Integration with Machine in which Engine is Installed

The 2G Eco-Governor supports CAN communication and is able both to transmit information such as engine speed, load, or alarms to the control system of the host machine, and to control the engine operating conditions in accordance with commands sent from the host machine system. Therefore, it would be possible to develop a system for a machine fitted with hydraulic equipment, for example, that uses this functionality to operate in a way that achieves the best fuel consumption by controlling the hydraulics and the engine load/speed in tandem.

4. Conclusions

The following summarizes the main features of the 3TNV80FT engine described in this report.

- By optimally matching the turbocharger to the engine and using the 2G Eco-Governor to control the fuel injection amount, the new engine achieves world-class levels of torque performance for a sub-19 kW engine while also complying with the emissions regulations of developed nations.

- Optimal control of the fuel injection amount by the 2G Eco-Governor minimizes the drop in output at high altitude (where air pressure is low), maintaining excellent torque performance under these conditions.

- Use of the communication capabilities of the 2G Eco-Governor has the potential to provide a variety of benefits in response to requests from the machine in which the engine is installed.

While there has been a notable emergence of hybrid and fully electric systems as power sources in recent years, in the case of industrial applications, diesel engines are expected to retain their superiority in terms of durability and reliability for some time yet. Yanmar intends to continue developing technology for diesel engines as it strives to supply products that maximize lifetime value for customers.

-IMPORTANT-

The original technical report is written in Japanese.

This document was translated by Research & Development Management Division.

Author