Development Division

YANMAR ENERGY SYSTEM CO.,LTD

YANMAR Technical Review

Development of All-In-One Hybrid Air-Conditioning System: New Air Conditioning System Concept to Take Advantage of Liberalization of Electricity and Gas Markets

Abstract

With Japan having begun liberalizing its electricity and gas markets in 2017, there is demand from customers for systems that are able to switch between different energy sources. In response to this market demand, Yanmar has launched a new hybrid air conditioning system that incorporates both an electric motor driven compressor and gas engine driven compressor. This all-in-one structure is the only one of its type on the market.

1.Introduction

As a consequence of the constrained balance of supply and demand for electric power since the Great East Japan Earthquake, there has been steady growth in sale volumes for gas heat pumps (GHPs). This is both in recognition of their energy efficiency and due to a combination of factors that include the growing adoption of heating and cooling for public schools and strengthening demand for replacement to existing systems. This sales growth has also been coupled with rising interest in energy costs due to the major liberalization in the markets for electric power and gas. To further expand sales of GHPs in this environment, Yanmar has developed a hybrid air conditioning system based on a new concept of providing a choice of gas or electric power as the energy source. This article describes the system.

2. Development Background

Energy markets have changed significantly in Japan over recent years with customers now having the freedom to choose where to purchase their energy thanks to the full liberalization of the retail electricity market in 2016 and the freeing up of the market for town gas from 2017. This is creating an increasing need for equipment that offers a flexible choice of energy source based on the customer's demand situation and energy pricing plans. To meet the needs of such customers, Yanmar has developed a hybrid air conditioning system that can operate on either gas or electricity, or both at once.

3. Product Overview

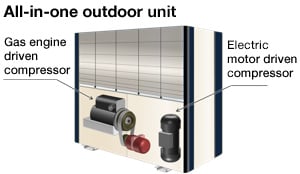

For most people, the term "hybrid" conjures up an image of hybrid cars, which typically combine a gasoline engine and battery-powered electric motor and work by automatically switching between these two power sources based on driving conditions. In contrast, a hybrid air conditioning system incorporates both a gas engine and an electric motor to drive its compressor.

Table 1 shows the different structures of hybrid air conditioning system. Whereas the Yanmar system combines all the components in the same unit, hybrid GHP systems from other manufactures use what is known as the multi outdoor system, meaning they have separate outdoor units. The all-in-one hybrid air conditioning system is exclusive to Yanmar, this being the first such model to be launched on the market.

Table 1 Types of Hybrid Air Conditioning System Structure

| Yanmar | Other GHP manufacturer | |

|---|---|---|

| Outdoor unit | All-in-one | Separated outdoor units |

| Conceptual diagram |  |

|

| Description of function | A compressor integrated with an electric motor is installed in the same refrigerant cycle for the gas engine driven compressor. The electric compressor works with a grid power. The same outdoor unit contains compressors with two different sources of drive power. |

A compressor integrated with an electric motor is installed in the same refrigerant cycle for the gas engine driven compressor. The electric compressor works with a grid power. The gas engine compressor and electric compressor are installed in the separate outdoor units that are connected by refrigerant pipes. |

4. Product Features

The Yanmar hybrid air conditioning system has a 85 kW air conditioning capacity, of which 62 kW is provided by the gas engine driven compressor (hereinafter referred to as gas engine compressor) and 23 kW by the electric motor driven compressor (electric compressor). The typical operating patterns used in practice are as follows.

- (1)When the air conditioning load is low and supply of electric power exceeds demand, such as early morning or night, the system operates using only the more efficient electric compressor.

- (2)During the day when the air conditioning load is high and electric power is in short supply, the system mainly operates using the gas engine compressor and focuses on minimizing electric power demand by only using the electric compressor to assist capacity at times of peak load.

The hybrid air conditioning system can also minimize cost and energy use for individual customers by using a remote monitoring adaptor to control its operation based on the customer's energy pricing plan and demand information.

(1) Development of all-in-one system

The advantages of an all-in-one hybrid system include its being more compact and easier to install, and its consistency of appearance when multiple units are installed.

Another advantage of the all-in-one system is that, whereas it can continue to utilize the full surface area of the outdoor heat exchanger when a low air conditioning load allows it to operate on a single power source (electric motor or gas engine only), the multi outdoor unit system used by other manufactures have less heat exchanger capacity available when operating on a single power source because in this case the outdoor unit of the unused power source is shut down. This provides the all-in-one system with a performance advantage, with an anticipated improvement of approximately 15 % in heat exchanger capacity when operating under low load compared to a multi outdoor system.

Yanmar developed its all-in-one hybrid system by:

① Engine downsizing, taking advantage of the wide range of available gas engines that comes from being an engine manufacturer.

② Developing a refrigeration cycle with a shared oil separator.

Of particular note, Yanmar has acquired a number of patents for the technology developed for use in the refrigeration cycle with a shared oil separator.

(2) Efficiency improvement

Both electric heat pumps (EHPs), which operate using an electric compressor only, and GHPs, which operate using a gas engine compressor only, have operating regions where their efficiency is low. In contrast, hybrid air conditioning systems can improve efficiency across a wide operating range by utilizing the power source that has the best efficiency for the air conditioning load at any given time.

(3) Optimal control for ratio of gas and electric operation

The hybrid air conditioning system was equipped with two separate operation modes that allow customers to choose cost-efficient or energy-efficient operation.

The remote monitoring adapter controls system operation by calculating how to minimize either charges for gas and electricity use (in cost-efficient mode) or the system's primary energy use (in energy-efficient mode). Specifically, it estimates energy use based on the air conditioning load at different times of the day for the cases when preference is given to using the electric compressor (A) and gas engine compressor (B) respectively. In energy-efficient mode, it estimates consumptions (A) and (B) and selects the lower of the two. In cost-efficient mode, it calculates the running cost by multiplying consumptions (A) and (B) by their respective energy prices and selects the option with the lower running cost.

Fig. 5 [1] shows an example of nighttime operation with low air conditioning load and a low electricity price. The power source efficiencies shown in Fig. 4 indicate that the electric compressor is more efficient than the gas engine compressor at low air conditioning loads. As the electricity price is also lower at night, cost-efficient operation is achieved when preference is given to using the electric compressor. Fig. 5 [2] shows an example of daytime operation with high air conditioning load and a high electricity price. As cost-efficient operation under these conditions is achieved by minimizing electricity consumption, giving preference to using the gas engine compressor is indicated.

In this way, the ability of hybrid systems to switch operation mode based on the energy price means they can operate in the way that is most cost-efficient under the conditions, even when energy prices or pricing plans change.

(4) Demand cut function

The remote monitoring adaptor has a demand cutting function that uses a pulse input to obtain the total power use for the building and operates the system so as to prevent this power use from exceeding a target demand specified based on the electricity contract. This function can help to reduce the customer's power bill by minimizing the building's peak demand. By using the gas engine and keeping use of the electric motor to a minimum, the hybrid air conditioning system can maintain a high level of air conditioning capacity even when electric power is in short supply. This ability to cut electricity demand without overly compromising air conditioning is a unique feature of hybrid air conditioning systems.

(5) Provision of information about operating conditions

To clarify energy savings and identify wasteful operation, customers can use a personal computer to view the operating conditions for the hybrid air conditioning system via the Internet. This uses operational data recorded at 30-minute intervals and stored at a remote monitoring center to show users trend graphs of operation over a day, month, or year, or a comparison of running costs against the typical case of using an EHP.

5. Conclusions

The hybrid air conditioning system described in this article is the most advanced form of air conditioning in terms of its ability to cope with changing energy markets. Given its ability to adapt flexibly and reliably to changes in the energy supply in Japan and elsewhere, Yanmar is confident that the benefits of the system will be able to be enjoyed by many people.

-IMPORTANT-

The original technical report is written in Japanese.

This document was translated by Research & Development Management Division.

Author