Development Division

YANMAR ENERGY SYSTEM CO.,LTD.

YANMAR Technical Review

Technology x Design:GHP K1series Development(XAIRⅡ)

Abstract

The new GHP K1 series launched by YES is an upgrade of the previous J series. GHPs have contributed to both energy conservation and electric power saving during the electricity shortages in the aftermath of the Great East Japan Earthquake. The new K1 series models feature enhanced efficiency and a new exterior design, with higher efficiency achieved through a range of improvements targeting different levels of air conditioning load.

This article describes the technologies adopted to achieve these improvements and the new design.

1. Introduction

With Japan having suffered from electricity shortages since the Great East Japan Earthquake, the GHP XAIR has achieved good sales since its product launch in April 2011, contributing to both energy conservation and electric power savings.

Gas engine heat pumps (GHPs) have played a major role in electric power load smoothing since the first model was released in 1987, and ongoing development has also added energy efficiency as a key feature, with the economic performance of the product over its entire lifecycle being a major strength.

Building on this foundation, Yanmar Energy System (YES) has now developed the ultra-efficient GHP XAIR II (YES product name: K1 series) to contribute to the reliability of national energy infrastructure by further enhancing the efficiency of GHPs.

2. Development Background

A JIS (Japanese Industrial Standards) product standard exists for GHPs. The JIS for GHPs has been revised in accordance with the JIS revision for EHPs, which is comercial-use direct-expansion type electric heat pumps. The main point of this revision was the primary annual performance factor (APFp)*. Whereas the previous JIS calculated the APFp at two points which are rated and medium loads, the revised standard considers the minimum load case as well. It also requires that consumed electric power measurements be performed at medium and minimum loads as well as the rated load measurement required by the previous JIS. These two points have a major influence on APFp, and the revision was made in the belief that it would provide a more accurate evaluation by aligning testing with actual use. In accordance with the thinking behind the new JIS, YES developed the K1 series with targets for each level of air conditioning load.

In keeping with the K1 series’ positioning as the latest model featuring improved environmental performance, YES also updated the exterior design to give it an attractive appearance that reflects its performance.

- ∗: The primary annual performance factor (APFp) is the ratio of thermal energy (kWh) worked by an air conditioner to its primary energy consumption (kWh) over the period of a year. Essentially, it is the annual efficiency of the air conditioner.

3. Product Summary

Fig. 1 shows a photograph of a K1 series air conditioner. The new design was led by Ken Okuyama, an international industrial designer. It has a solid appearance featuring vertical lines on the four corners with two-tone coloring. While hiding screws on the external panels as much as possible was a core design objective, the unit was made easy to work on by leaving them uncovered intentionally where required for maintenance. Furthermore, the spacing of the protective net over the heat exchanger narrows from top to bottom to prevent small children from inserting their fingers through the lower parts.

Fig. 2 shows the efficiency improvement by comparing the APFp for the old and new series using YES estimates (as it is not possible to calculate APFp accurately for the old model based on the new JIS standard). The old model was a J series product.

As shown in Fig. 2, the efficiency has significantly improved by between 20 and 27% compared to the old J series. Table 1 lists the APFp values for the K1 series.

Table 1. K1 Series APFp

4. Product Features

As noted above, the K1 series was developed to meet targets for different air conditioning loads. The following sections describe these in more detail.

(1) Expanded engine speed range

In response to the requirement in the new JIS of evaluating performance at the minimum load as well as rated and medium loads, the operating speed range of the engine was expanded by reducing its minimum speed from 650 min-1 (on the previous model) to 500 min-1. This reduction in minimum speed expanded the range of conditions under which the engine could operate continuously rather than use intermittent operation (whereby the engine was alternately turned on and off) as in the past to match low air conditioning loads. This improved efficiency at low load, with an approximate 8% increase in APFp. While the challenges for low-speed operation include the stability of engine combustion and speed control, these were overcome by improving engine combustion-related components, such as the mixer and spark plug, and improving the engine control software. However, this still left the problem of engine vibration at low speed. While other manufacturers produce GHPs that are able to operate at 500 min-1, none of these use a three-cylinder engine. Maintaining stability at low speed becomes more difficult the smaller the engine is, with fewer cylinders meaning greater low-speed vibration. Given the need to overcome this problem, structural mechanisms were adopted on the K1 series both to isolate and absorb vibrations. These were incorporated along with the new external design.

(2) Air/refrigerant heat exchanger and refrigerant/refrigerant heat exchanger

As the rated output of the engine used to drive the air conditioner can be kept to a minimum by increasing the refrigerating performance at medium and high loads, enabling engine downsizing and a better APFp. And then efficiency improvements was also made at medium and high loads. One such measure was to revise the flow of refrigerant in the air/refrigerant heat exchanger. The concept behind the flow of refrigerant in the air/refrigerant heat exchanger, which had remained unchanged in several previous YES models, was significantly improved for the K1 series. Fig. 3 shows an overview. In previous models, counter-flow of refrigerant in the downwind-to-upwind direction was used for both the dual-phase region and SC (subcooling, fluid) region. On the K1 series, in contrast, the two regions are kept separate by an intermediate header. This increases the flexibility of design for each region by enabling the optimal refrigerant flow rates to be selected for the dual-phase and SC regions independently. This achieved an approximate 8% improvement in APFp through higher performance at medium and high loads.

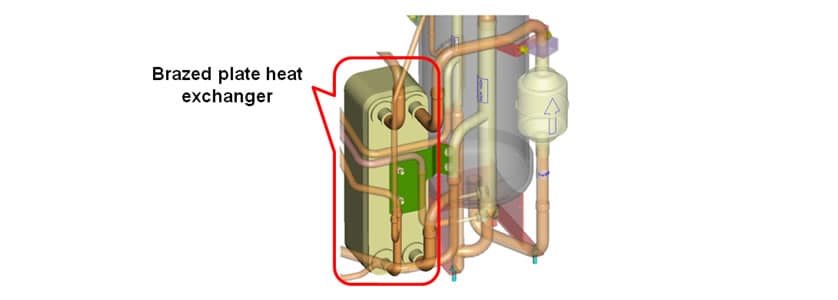

A second measure was the addition of a refrigerant/refrigerant heat exchanger. Whereas the previous model had a heat exchanger (called the “SC coil”) in the receiver to ensure supercooling of the refrigerant, this was replaced with a brazed plate refrigerant/refrigerant heat exchanger in the K1 series (see Fig. 4 (25 HP and higher)). This provided increasing of the heat exchange capacity of the SC heat exchanger, decreasing the flow rate of refrigerant through the indoor units, decreasing pressure losses between indoor units and the compressor, increasing of refrigeration cycle efficiency at medium and high loads and consequently improvement of the APFp by approximately 2% .

(3) Large-diameter propeller fan and electrical equipment

In addition to performances and gas consumption, the new JIS also stipulates consumed electric power measurements at rated, medium, minimum, and maximum test conditions. As the reduction of electric power consumption is effective not only to reduce energy consumption but also to save electric power, the K1 series was designed to reduce electric power consumption over the entire load ranges. The first measure for this purpose was to adopt the large-diameter propeller fan and to optimize the shape of the shroud (see Fig. 5). The propeller fan diameter was enlarged from 610 to 650 mm to increase the flow of air relative to the fan speed, and the shape of the shroud was optimized to reduce air flow losses. This achieved an approximate 7% improvement in APFp by increasing fan efficiency over the entire load range.

Next, to reduce electric power consumption of electrical equipment, the component count was reduced, including cutting the number of controllers and the number of electromagnetic valves used for controlling refrigerant. Measures were also adopted to reduce base power losses by improving the efficiency of the transformer and other power supply equipment. These power saving measures achieved an approximate 2% improvement in APFp.

Along with some other additional enhancements, the improvements described above collectively improved APFp by approximately 24% on average. Furthermore, the performance improvements and new exterior design were achieved without changing the external dimensions. Table 2 lists the main performance and other specifications.

Table 2 Main Performance and Other Specifications of K1 Series

(4) K1 series product range

The K1 series was launched this Fall as the XAIR II, available in models from 16 to 30 HP. Whereas the previous models included special variants for the replacement market, recognizing that replacements now make up a growing proportion of the market, the K1 series has incorporated functions specific to the replacement market as standard features. (In particular, a function for automatically detecting the correct refrigerant charge rather than requiring a design calculation to determine the amount based on the length of refrigerant piping. This feature is also provided on the W-multi model). This means the same models can be used for both standard and replacement installations. The addition of further variants to the product range is planned by March 2016. These are listed in Table 3.

Table 3 K1 Series Product Range

5. Conclusions and Future Plans

By delivering higher efficiency than the XAIR models, the GHP XAIR II K1 series described in this article provides products that convey an even higher dimensional sense of the advantages of gas air conditioning in Japan, where there is a growing awareness of the need to save electric power. Furthermore, YES believes that the updated exterior design invokes a “satisfaction of ownership” that one does not get from normal plants and equipment. The aim is to enhance the status of gas air conditioning in terms of both high efficiency and design.

Meanwhile, electricity shortages and environmental problems such as global warming are issues for the entire world, not only Japan. GHPs can provide solutions to these problems in the form of gas air conditioning, and in Japan these devices have become established as a proven product category. Despite this, there remains little awareness of GHPs outside Japan. YES aims to contribute to solving energy and environmental problems throughout the world by using the K1 series as a weapon for a new assault on overseas markets.

-IMPORTANT-

The original technical report is written in Japanese.

This document was translated by R&D Management Division.

Author