Development Division

Large Power Products Operations Business

YANMAR Technical Review

High Reliability and Environmentally-friendly Mechanical Controlled Commercial Marine Diesel Engine 6CXB-GT

Abstract

The development concept of the 6CXB-GT marine propulsion engine was to create an “Earth-friendly engine,” with the key objectives being “low fuel consumption,” “low emissions,” “high power,” and “high reliability.” While use of electronic control could be expected to facilitate fuel-efficiency and low emissions, Yanmar instead made use of robust mechanical control to achieve its top priority of reliability. The development took three years and succeeded in achieving all four objectives. Fuel consumption was reduced by 8 to 10%, emissions achieved compliance with IMO Tier 2 and CCNR (Central Commision for the Navigation of the Rhine) regulations, and the engine output power is the highest in Japan’s class A category for fishing boats. High reliability, meanwhile, was achieved through exclusive use of mechanical control for combustion matching.

1. Engine Overview

Because the time taken to travel to and from the fishery can have a significant impact on fish catches and price, the development and commercialization of marine engines for the Japanese fishing boat market has in the past placed top priority on light weight and high output due to the strong demand for fast speed boats. Since the sudden rise in fuel prices in 2008, however, there has been a change in customer preferences, with very strong demand for low fuel consumption as well as high output. This strong interest in fuel consumption extends beyond the fishing boat market, also including passenger and cargo vessels, with demand for engine downsizing to save on fuel and reduce costs while maintaining the same output.

There has also been a tightening since 2011 in the nitrogen oxide (NOX) emission regulations stipulated by the International Maritime Organization (IMO). Furthermore, in order to open up new markets in Europe, the 6CXB-GT engine also needed to comply with the European environmental regulations stipulated by the CCNR, which are more stringent than those of the IMO. Market demand for reductions in carbon dioxide (CO2) emissions to help prevent global warming is also growing. Unfortunately, there are typically trade-offs between the objectives of low fuel consumption, low emissions, and high output, making it very difficult to achieve all three at once. Together with these, there is also a need to ensure the reliability of marine propulsion engines because of the crucial role they play in safety and protecting life at sea.

Accordingly, Yanmar chose “Earth-friendly engine” as the development concept for the 6CXB-GT engine and embarked on development with the aim of achieving the four objectives described above, namely “low fuel consumption,” “low emissions,” “high power,” and “high reliability.” Although the adoption of electronic control is one way to achieve low fuel consumption and low emissions, because there is little history of using electronic control in commercial marine propulsion engines, Yanmar chose to place top priority on reliability by using mechanical control instead. To date, Yanmar has spent three years on the development, making maximum use of its technology as a leading manufacturer of marine propulsion engines, and succeeding in overcoming the challenges presented by the four objectives. Fuel consumption has been reduced by 8 to 10% compared to previous models, receiving the type approval certificate of a high level environmental performance engine under the government. In terms of low emissions, the engine has been certified as complying with IMO Tier 2 and also satisfies the CCNR regulations. The engine also has achieved the highest output in Japan’s class A category for fishing boats.

2. Technical Features and Benefits

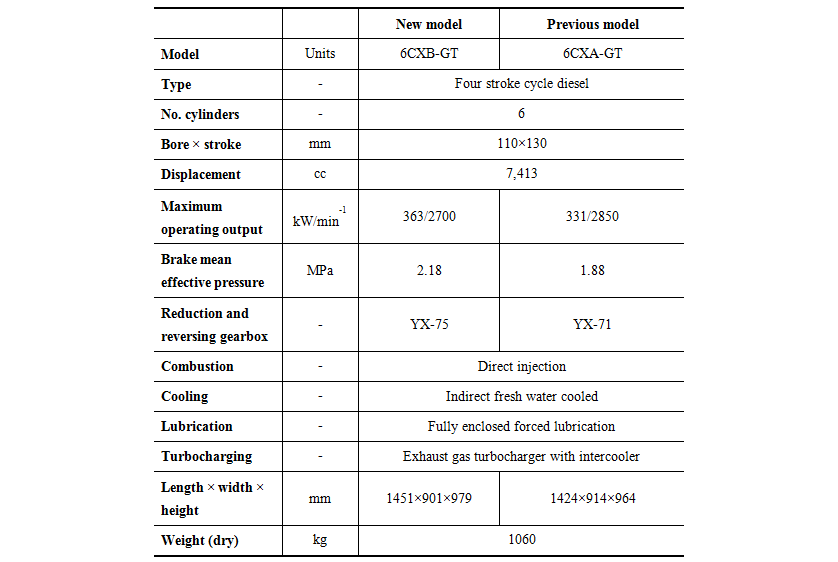

Table 1 Comparison of Engine Specifications of 6CXB-GT and Previous Model

2.1 Technical Features

(1) Use of mechanical control

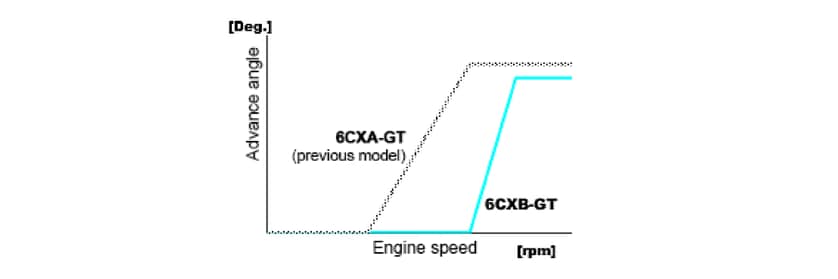

Rather than using electronic control for the fuel injection system, which is the basis of engine combustion performance, the engine uses entirely mechanical control. As a result, Yanmar selected a high-pressure injector pump to improve combustion efficiency through fuel atomization and the use of a new injection timer that determines the injection timing dynamically (see Fig. 2).

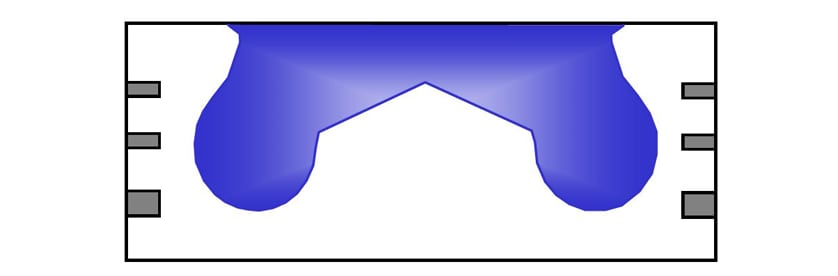

(2) Lowλ※1combustion

A problem with past combustion systems has been that less air volume has led to decreasing of output and increasing of exhaust black smoke. In response, the 6CXB-GT uses a special “squish lip” shape for the piston combustion chamber (see Fig. 3) that improves combustion efficiency to achieve low λ combustion.

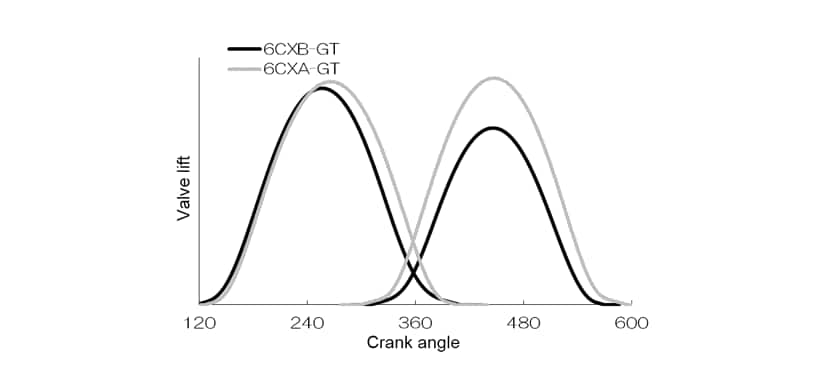

Low λ combustion enables the inlet and exhaust valve timings and valve lift (see Fig. 4) to be modified to reduce pumping losses and achieve low fuel consumption and emissions.

※1 It indicates excess air ratio. λ = Actual air fuel ratio/theoretical air fuel ratio

(3) Optimization for combustion using multivariable analysis

Numerous factors in addition to those mentioned above go into setting fuel specifications and the matrix includes a huge number of terms. In developing the 6CXB-GT, Yanmar established quantitative formulas for NOX, fuel and other terms by conducting multivariable analysis with approximately 140 explanatory variables (parameters with the potential to influence performance) (see Fig. 5). These formulas were used to identify which factors had an influence on performance and to what extent they are in order to conduct optimization testing.

2.2 Benefits

(1) Low fuel consumption and low emissions

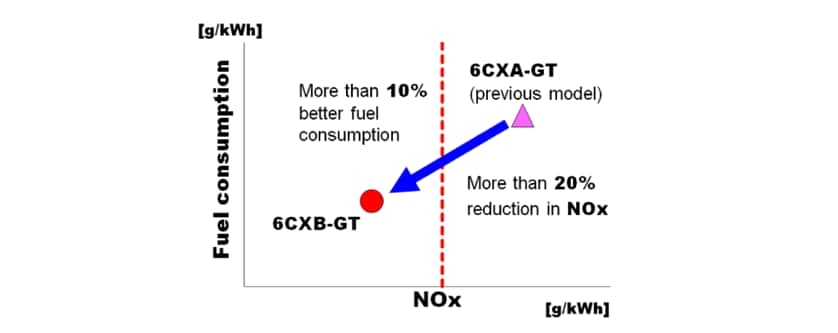

The 6CXB-GT achieves NOX levels that are significantly below those required under the IMO regulations, and more than 20% below those of the previous model. Fuel consumption has also been reduced by more than 10% compared to the previous model despite the trade-offs between this parameter and NOX (see Fig. 6).

(2) High output

The engine achieves the highest ratio of output to displacement among engines of 10 L or less in class A category for fishingboats under Japan's Fishing Boat Act, leading the class in terms of its compact, high-output design (see Fig. 7).

3. Results

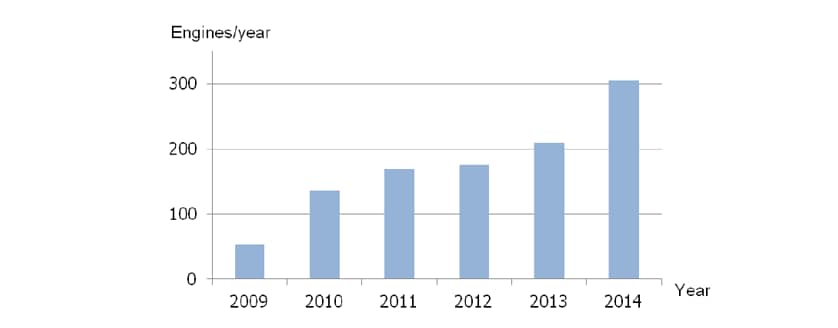

Since production commenced in June 2009, 6CXB-GT marine propulsion engines have been installed in fishing, passenger, cargo, coast guard, and other types of boat, achieving and maintaining a Japanese market share of 50% or more within the relevant horsepower ranges. Sales for overseas markets commenced in December 2009. And in 2014, annual shipments had counted more than 300 engines, with a cumulative total of more than 1,000 units. Engines in use include some that have run up more than 10,000 hours, delivering sufficient reliability for customers. The engine also won the Agency of Natural Resources and Energy Director’s Award at the Energy-Efficiency Machinery Awards held by The Japan Machinery Federation in February 2014.

-IMPORTANT-

The original technical report is written in Japanese.

This document was translated by R&D Management Division.

Author