Mini excavator: how to choose in 2025

A mini excavator belongs to the category of construction machinery. It is specially designed for earthmoving, excavation, demolition and landscaping work. It is an excellent alternative to backhoe loaders and heavy-duty excavators because its compact size means it can go anywhere!

It is also known as a mini-digger or compact excavator. As its name suggests, this is a micro excavator that can generally weigh between 800 kg and 6 tonnes. It can be used in a wide range of sectors, including building and public works, landscaping, forestry, roadworks, recycling, demolition and agriculture.

With constant technological advances, choosing the best mini excavator in 2025 requires a thorough understanding of the features, performance and technologies available on the market. This guide aims to simplify the selection process by highlighting the key aspects to be considered.

- 1. Characteristics and composition

- 2. Operation of the mini excavator

- 3. The different models

- 4. Spotlight on the electric mini excavator

- 5. Maintaining your mini excavator

- 6. Mini excavators for private and professional use

- 7. Buying new, leasing or second-hand?

- 8. Which accessories for which types of work?

- 9. Focus on trailers

1. Characteristics and composition

Composition

Here is a non-exhaustive list of the components that make up a mini excavator, so that the operator can carry out their work:

- Track-mounted under-carriage

- Upper frame

- Operator station in cab or canopy version (without windows, with a metal structure)

- Reset mechanism

- Engine

- Hydraulic system

- Accessories such as:

- Quick couplers

- Bucket

- Levelling blade

- Tracks or wheels

Technical specifications

Essential characteristics to be taken into account on a mini excavator depending on your work are as follows:

- Arm digging force

- Pull-out force

- Dimensions

- Rear tall swing

- Digging depth

- Compactness (with or without retractable track)

- Hydraulic flow

- Maximum working pressure

- Maximum unloading height

- Lifting capacities

- Radius of rotation (rear tall swing)

- Travel speed

- Transport and operating weight

- Engine

The operating weight of the mini excavator is a crucial element. It determines the machine's stability and load capacity. Make sure you choose a mini excavator whose weight matches the nature of the terrain on which it will be used. The size of the mini excavator must also be adapted to the dimensions of the work areas to ensure optimum manoeuvrability.

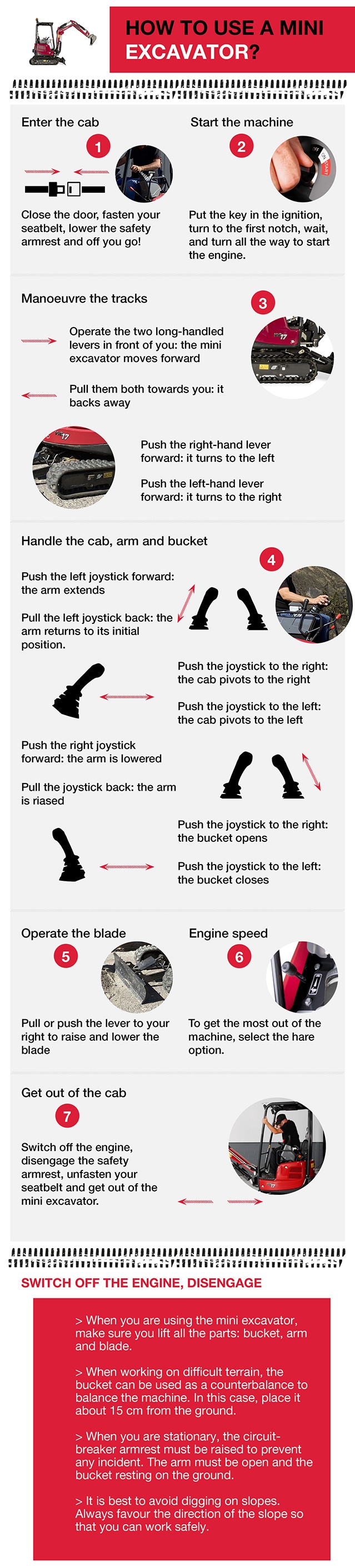

2. Operation of the mini excavator

Even if it is regularly used and easy to handle, operating a mini excavator requires a certain amount of skill. Once you are familiarised with it, you need to practise so that your movements are properly synchronised. Here's how to get started with your mini excavator:

Enter the cab

When you are in the cab, safety should be your primary concern. Close the door. It may seem really basic, but remember to fasten your seatbelt. This would ensure that you will not experience any shocks every time the ground becomes unstable or the arm of the mini excavator moves. Adjust the rear-view mirrors. Check the battery switch.

Lower the safety armrest (you can spot it by the red handle), it acts as a circuit breaker. This will unlock the controls and allow you to start the machine.

Start the machine

Put the key in the ignition and turn to the first notch, the lights on the on-board display will light up (wait for the machine's display to initialise if there is no display, wait for 5 seconds), then turn the key clockwise as far as it will go to start the engine. As with a car, we recommend that you leave the engine running for about thirty seconds before starting work.

Operate the tracks

The two long-handled pedals or levers in front of you are for operating the tracks. Here are the possible actions:

Push both forward: the mini excavator moves forward

Pull both towards you: the mini excavator moves back

Push the right-hand lever forward: the mini excavator turns to the left.

Push the left-hand lever forward: the mini excavator turns to the right.

NB: If you push one lever forwards and the other backwards, the mini excavator will turn on the spot. If your cab is rear-facing, the controls are not reversed, but your markings are.

Handle the cab, arm and bucket

The two joysticks on either side of the seat are the mini excavator's main controls. They allow you to control the rotation of the cab and use the arm and the bucket.

Push the left joystick forward: the lever arm extends

Pull the left joystick back: the lever arm moves back

Push the joystick to the right: the upper frame rotates to the right.

Push the joystick to the left: the upper frame rotates to the left.

Push the right joystick forward: the arrow is lowered

Pull the joystick back: the arrow is raised

Push the joystick to the right: the bucket opens.

Push the joystick to the left: the bucket closes.

Operate the blade

You will find a lever on your right next to the armrest (on most machines). Pull and/or push it to raise and lower the blade.

Engine speed

To vary the power of the mini excavator, you can vary the engine speed. You will easily recognise this control thanks to the hare and tortoise images. For optimum performance, select the hare on the hand throttle.

Get out of the cab

Once your work is done, remember to look after your own safety and that of others. Start by switching off the engine. Fold up the safety armrest to switch off the hydraulics and avoid any risk of mishandling. Finally, unbuckle your belt and step off the mini excavator.

Additional tips and tricks

- When you are using the mini excavator, make sure you lift all the parts: bucket, arm and blade. The bucket should be about 30 cm above the ground.

- When working on difficult terrain, the bucket can be used as a counterbalance to balance the machine. In this case, place it about 15 cm from the ground.

- When you are stationary, the circuit-breaker armrest must be raised to prevent any incident. The arm must be open and the bucket resting on the ground.

- It is best to avoid digging on slopes. Always favour the direction of the slope so that you can work safely.

- You may not be able to dig in line with your trench (if you have to go round a tree or dig against a wall). In this case, you can rotate the arm of the mini excavator using the right-hand pedal or the roller on the joystick.

3. The different models (tracks, tyres, internal combustion or electric motor)

There are several types of mini excavator, here are the main categories:

Mini excavators on tracks

These are the most common. They are highly effective on unstable sites. The tracks give them better weight distribution on the ground. In short, they are extremely stable, even on rough terrain. The tracks reduce soil compaction by distributing the weight of the machine more evenly over the tracks.

Compact wheeled excavators

They are best suited to stable sites such as pavements or concrete slabs in warehouses or on flat ground. And also on “network” sites where significant distances have to be covered. Their stability is ensured by stabilisers and/or levelling blades independent of the wheels.

Mini excavators with combustion engines

They run on petrol, diesel or biofuel. Their high battery life is their main advantage.

Electric mini excavators

Environmentally friendly, quiet and efficient, they are a good alternative to internal combustion engines. They are powered by several batteries. Battery life will depend on the capacity of the battery pack and the type of work carried out with the mini excavator. You can generally work for 3 to 4 hours when the charge is full. It takes between 2 and 3 hours of rapid charging to recharge.

4. Spotlight on the electric mini excavator

Electric generation opens up new perspective. It allows you to work with significantly reduced noise levels and zero CO2 emissions in urban environments. There are many legitimate questions on this subject. Are they as efficient as combustion engine machines? What exactly is the capacity? Are they suitable for all types of work?

In short, one of the key advantages of this solution is its ability to operate discretely, which changes the image of urban works and makes the mini excavator more respectful of the environment. The absence of exhaust fumes is also an added advantage. Maintenance costs are also lower, because apart from the usual hydraulic system oil changes, the electric motor requires almost no servicing.

5. Maintaining your mini excavator

After each use, you can clean your mini excavator before storing it. All you need to do is position the machine on a stable, flat surface. Make sure it is switched off. Do not use the high-pressure cleaner or water jet directly on the electronic components under the bonnet. Spray the entire surface of the machine with specialist liquid soap. Clean with a pressurised water jet. Pay attention to the upper frame bearing and eliminate foreign elements in the ring gear of the planetary gear train. The vacuum cleaner can then be used to clean the lower part of the cab. A soft, damp cloth can be used to clean the upper part of the passenger compartment.

Cleaning your machine will allow you to quickly detect any leaks or faulty parts. Remember to use a grease gun to lubricate your machine.

Maintenance and inspection intervals may differ for certain machines. Generally, the following is recommended for mini excavators*:

| 250 hours | Replacing the fuel filter |

|---|---|

| 500 hours | Changing the engine oil and filter Replacing the hydraulic oil filter Replacing the hydraulic oil return filter |

| 1000 hours | Replacing the hydraulic oil |

| 2000 hours | Replacing the coolant |

Example of a periodic inspection and maintenance table for a Yanmar ViO17.

- *Refer to your mini excavator's user manual for more information.

6. Mini excavators for private and professional use

Generally, mini excavators weighing less than 2.5 tonnes are used for work in narrow areas or on sensitive ground such as lawns or pavilion interiors.

Moreover, the retractable tracks allow easy access in most cases.

Machines up to 2.5T allow you to transport them on a trailer with an E licence. Watch out for overloading!

For more intensive use, the most suitable models are those over 2.5 tonnes. These are easier to make profitable, especially when renting.

7. Buying new, leasing or second-hand?

Purchase price

More expensive to buy and also safer, new prices for a mini excavator are very variable depending on the manufacturer. On average, we can estimate a range of between €15,000 and €150,000. This difference is due to the weight of the machine and therefore the technology used:

- ± €18,000 for a 1-tonne mini excavator

- ± €20,000 for a 1.5 tonne mini excavator

- ± €30,000 for a 2.5 tonne mini excavator

- ± €40,000 for a 3.5 tonne mini excavator

- Between €50,000 and €65,000 for a 5.5 tonne mini excavator

- ± €70,000 for a 7-tonne mini excavator

- Between €100,000 and €150,000 for a mini excavator weighing less than 10 tonnes

The prices quoted here are indicative only.

Rental rates for a mini excavator

Prices are based on the weight of the mini excavator. They can vary from €100 to €1,000 per day, depending on the machine.

| Mini excavator model | 1 to 4 days of rental | 5 to 20 days of rental | More than 21 days of rental | Weekend |

|---|---|---|---|---|

| Mini excavator under one tonne | 100 euros | 95 euros | 90 euros | 250 euros |

| 1.5 tonne mini excavator | 125 euros | 120 euros | 100 euros | 275 euros |

| 2.5 tonne mini excavator | 150 euros | 145 euros | 125 euros | 300 euros |

| 3.5 tonne mini excavator | 200 euros | 175 euros | 150 euros | 350 euros |

| 5.5 tonne mini excavator | 250 euros | 200 euros | 185 euros | 450 euros |

| 7 tonne mini excavator | 450 euros | 350 euros | 250 euros | 600 euros |

| Mini excavator under 10 tonnes | 500 euros | 450 euros | 350 euros | 750 euros |

Prices vary according to the distance between your home and the rental company. The further away you live, the higher the travel costs will be.

The criteria used to determine the rate:

- Duration of the lease

- Capacity of the mini excavator (weight, features, etc.)

- Mini excavator on tyres or tracks (slightly cheaper tyres)

- Rental with or without driver

- Added accessories

In many cases, insurance, maintenance and two or even three accessories are included in the rental price. However, delivery of the mini excavator and fuel are not included.

Find out the rates for mini excavators for rental in your region

Second-hand mini excavators

Cheaper than a new mini excavator, second-hand is a good solution. Check the machine's history carefully to avoid hidden defects. Choosing the right work tool is no easy task, especially with so many products on the market.

Wondering how to choose a second-hand mini excavator?

First you need to identify the work you want to undertake with your future mini excavator.

Do you need to carry out earthworks or dig trenches? A mini excavator would be essential. It will allow you to be efficient and quick on your worksites. It will also be sufficient for routing cables and pipes, as well as for building a swimming pool or carrying out foundation work.

It is also suitable for urban work on public roads, avoiding damage to the ground.

The cost of this equipment is significant, and sometimes the solution lies in buying a second-hand mini excavator.

Why buy a second-hand mini excavator?

Depending on your purpose, you may not have the budget to buy a new mini excavator.

Fortunately, there are some cost-saving solutions available.

You can choose to buy your own mini excavator, or you can contact a specialist to buy a second-hand one.

- If you are looking to buy a mini excavator for less than €30,000, you will find plenty of offers from both private individuals and professionals.

- Remember to check the number of hours, years, make and location of the machine.

- Do not hesitate to ask about smaller models, which are often more attractively priced and can have the same features as mini excavators.

- It is normal to have doubts, and it is perfectly possible to entrust the buying process to a professional in your area. They will be able to recommend certain models depending on the frequency of use and your budget.

The second-hand market remains a good alternative thanks to its value for money, whether for a private individual or a construction company.

Click here for second-hand mini excavator offers

8. Which accessories for which types of work?

The mini excavator has the advantage of being able to accommodate a wide range of attachments that can vary its field of action ad infinitum! There's an attachment for every application: landscaping, public works, forestry, recycling, demolition, etc. We have listed some of the most commonly used:

- grapple bucket

- mixing bucket

- screening bucket

- crusher bucket

- concrete crusher

- universal crusher

- scrap shears

- loader with or without grab

- brushcutter

- stump grinder

- delimber

- wood clamp

- pruning bar

- road milling machine

- bank mower

- sorting pliers

- demolition pliers

- post driver

- hydraulic magnet

- hydraulic rock breaker

- saw

- rake

- grapple

- snow blower

- ripper or breaker tooth

Remember to take into account the power and size of the mini excavator when choosing the right tool.

9. Focus on trailers

To transport your mini excavator, you will need a flatbed trailer to take the machine to your worksite. The flatbed trailer can be towed by a suitable vehicle: truck, 4x4.

It should be chosen in relation to the size of the mini excavator. It must be wide enough and long enough not to tip over.

There are rules in force for driving. A B driving licence is not enough. It is possible to take a 7-hour course to obtain a B96 licence. This licence is compulsory if you wish to tow a trailer weighing more than 0.75t with your vehicle when the Maximum permissible laden weight (MPLW) of the combination (vehicle + trailer) is more than 3.5t but no more than 4.25t.

A BE licence is compulsory for towing a trailer with a maximum permissible weight of between 0.75t and 3.5t, and if it exceeds 4.25t. This is the case, for example, for a 1.5t towing vehicle and a 3.5t trailer.

A trailer capable of towing more than 5T must have its own registration document. It will have its own number plate. You will need to declare it to your insurance company.

Finally, a plate bearing information about the manufacturer and the trailer must be attached to the drawbar.

Prices depend on the weight of the mini excavator:

| Weight of the mini excavator | Estimated prices |

|---|---|

| Between 1.3 and 2t | €2,000 to 2,200 |

| Between 2t and 2.6t | €2,000 to 2,900 |

| Between 3t and 3.5t | €2,400 to 3,200 |

Choosing the right mini excavator in 2025 requires a considered and informed approach. By carefully assessing your requirements, taking into account weight, power, technology and cost, you will be able to select a mini excavator that will optimise the efficiency of your operations while ensuring a sound investment. Take the time to compare the options available on the market and don't hesitate to consult industry experts for personalised advice.

We hope we have been able to give you a few pointers to help you with your project.

All the best.