News Release

New Yanmar Green Challenge 2050 Inspires Demonstration of Future-Proof Engine Capabilities at Workboat Show

November 29, 2022

Yanmar America Corporation

International Workboat Show, November 30 to December 2, Booth 2309

Promising new benefits for its commercial customers, Yanmar integrates its extensive, reliable engine line-up with a new company commitment to advance technology to meet the environmental challenges of the future at this year’s International Workboat Show.

The Yanmar marine divisions will showcase a full range of light-duty, high-speed, and larger engines, offering versatility, output range and quality for various applications, including workboats, rescue and safety boats, fishing and passenger vessels, salvage/towing, government service vessels, port authority boats and large offshore vessels.

In addition to the product line-up, Yanmar is demonstrating further capabilities specific to the commercial sector following the launch of the YANMAR GREEN CHALLENGE 2050 to eliminate greenhouse gas emissions in its business activities. The company, which has prioritized sustainability since its founding, will demonstrate how the initiative is steering product development and innovation, inspiring new fuel systems and concepts, and opening up exciting opportunities for partnerships with OEMs with the joint aim to reduce environmental impact.

Kevin Carlan, President, Yanmar Marine International Americas, said: “The Workboat Show is always a key date in the diary for us to showcase Yanmar’s focus in the commercial sector. For the first time, we can combine our leading engine range with evidence of how new Yanmar technology and developments will impact our ability to work with and benefit our customers and partners in the years ahead. Rooted by the mission of developing carbon reduction technologies across land, sea and city, Yanmar is already at the forefront in the development of alternative fuels, trialing a hydrogen fuel cell concept boat and leading the way in designing dual-fuel marine engines. Further work continues in methane oxidation catalyst systems. We see many opportunities with our commercial customers in line with the YANMAR GREEN CHALLENGE 2050, such as working with OEMs to be their electric systems integrator. We are looking forward to introducing this new impetus into our discussions at the show.”

Yanmar Engine Lineup

Yanmar Marine International (YMI) and Yanmar America’s combined offering for the commercial sector ensures customers and partners receive the cost and efficiency benefits of an engine line-up proven for its leading durability and extremely low fuel consumption.

The joint display will highlight the YMI range as the largest common rail recreation and light duty commercial (LDC) EPA-certified engine line-up, supported by the largest marine service network in the industry. Engineered for the harshest of conditions with the additional features required by the rigorous SOLAS (Safety Of Life At Sea) regulations, these Yanmar diesel engines are designed to exceed global emissions regulations and standards. Options also

include semi-2-pole, high-power alternators, NMEA connectivity and more, to satisfy nearly any light-duty commercial application requirement.

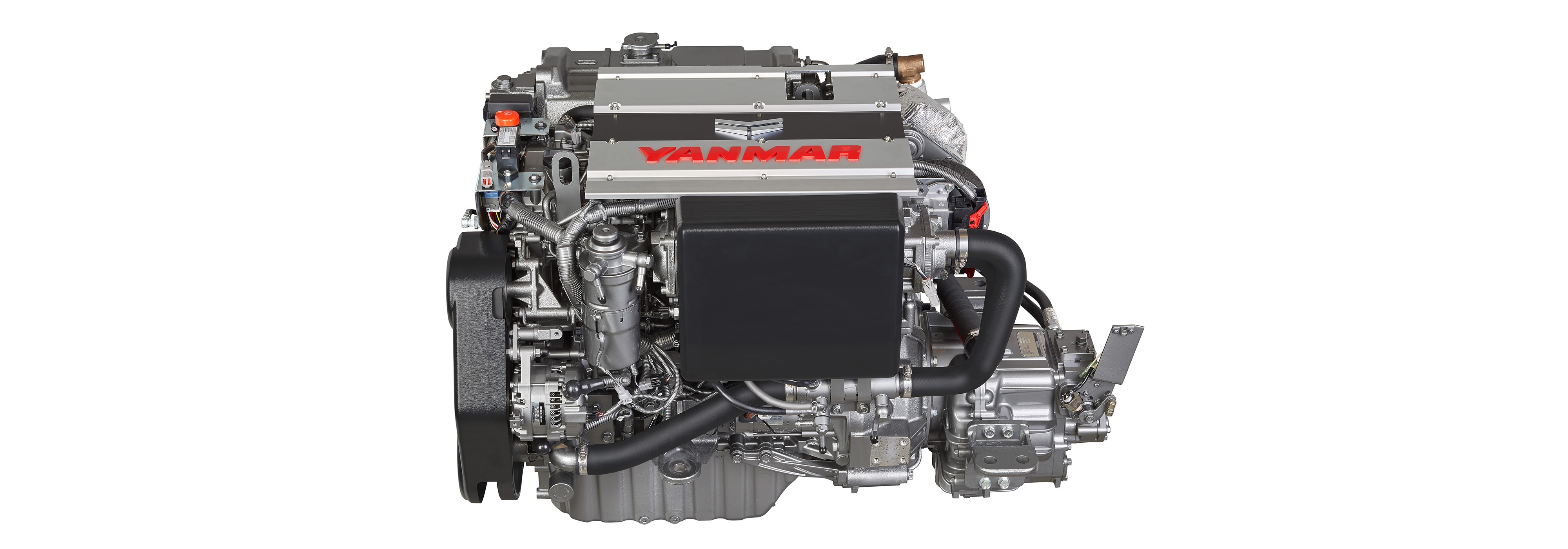

The units in the LDC range on display at Workboat this year are the EPA Tier III and IMO Tier II certified 4LV and 6LF engine series, well-suited for water taxis, high speed fishing vessels, pilot boats and government service vessels. The 4LV engines are cleaner, quieter and produce more torque and acceleration than any other engine in their class, while the 6LF models are compact and lightweight engines for semi-planing and planing lightweight hulls with inboard propulsion systems.

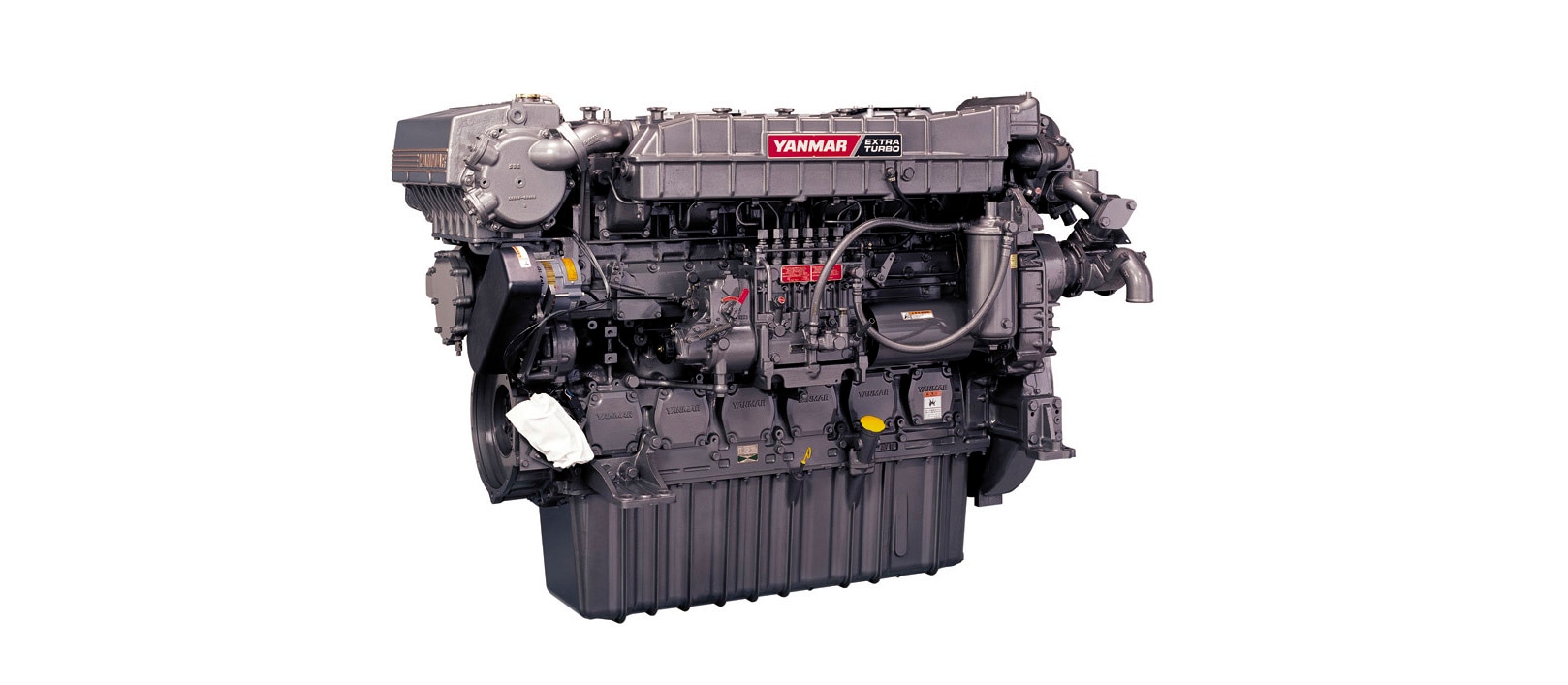

Yanmar America’s high-speed commercial (HSC) division will showcase the EPA Tier III, IMO Tier II and IMO Tier III (with SCR) 6AYEM-ET engine. The 6AY engines are renowned for their high output and high torque, long life and high reliability, easy maintenance, low fuel consumption and life cycle value.

The large-scale marine engines, which are used as power and energy sources for tugs, fishing vessels, tankers and other ships, achieve the high level of power, fuel economy and higher-dimensional durability required for the harsh open ocean waters. On display at Workboat, Yanmar’s large engine portfolio includes the 6EY17 unit, which is both IMO Tier II and IMO Tier III certified.

Further capabilities of the large engine business unit include its dual fuel 8EY26LDF marine engines, which run on diesel as well as environmentally friendly LNG, enabling them to satisfy IMO Tier III regulations. With features such as load fluctuation tracking, acceleration performance, and high thermal efficiency, in addition to precision air-fuel ratio control technology, 8EY26LDF engines always maintain optimum combustion, enabling them to deliver stable, highly reliable operations.

YANMAR GREEN CHALLENGE 2050 and new technology

Aiming to transform the company, YANMAR GREEN CHALLENGE 2050 declares its intention to eliminate greenhouse gas (GHG) emissions in its business activities and achieve zero environmental impact by circulating resources to realize a sustainable future.

Several projects and developments demonstrate progress in the marine sector, including:

- A field demonstration test for the maritime fuel cell system that incorporates hydrogen fuel cell modules from Toyota’s MIRAI automobile. The system was installed into Yanmar’s EX38A FC pleasure boat for field testing. Yanmar aims to verify specific issues and solutions in a maritime environment for the deployment of the maritime fuel cell system. The system is planned to be deployed to larger vessels by 2025. YANMAR was among the first companies to comply with environmental regulations with its development of dual-fuel marine engines.

- For the first time in the world, Approval in Principle was received for the Methane Oxidation Catalyst System from Nippon Kaiji Kyokai (ClassNK) for Hitachi Zosen Corporation, Mitsui O.S.K. Lines, Ltd. (MOL), and Yanmar Power Technologies Co. (YPT). The system reduces methane slip by placing a methane oxidation catalyst in an LNG fuel engine and oxidizing the methane. The project aims to further reduce the environmental impact of LNG fuel engines by achieving a methane slip reduction rate of more than 70% over a six-year period from FY2021 to FY2026 by combining a methane oxidation catalyst and engine improvements and verifying the design concept in actual vessels.

- The establishment of HyEng Corporation, where Kawasaki Heavy Industries, Ltd., Yanmar Power Technology Co., Ltd., and Japan Engine Corporation will pursue joint development of world-leading marine hydrogen-fueled engines. The three companies will further advance their joint development activities and accelerate their drive to develop new markets for decarbonization in the marine domain.

Visit Yanmar at the International Workboat Show from November 30 to December 2 Booth 2309.

About YANMAR Marine International

A leading supplier of innovative engines and technology-driven marine propulsion systems, Yanmar Marine International (YMI) supplies the world’s cleanest, most efficient, reliable and durable diesel engines for the recreational sector – both sailboats and powerboats – and light duty commercial applications. Its trusted range of common rail marine diesel engines encompass an output range from 40 mhp to 640 mhp, the most comprehensive offering available from any marine engine manufacturer. Committed to the development of advanced technology for the best and most sustainable solutions to meet the evolving needs of boat owners and OEMs, YMI’s mission is to enhance the entire boating experience for all its customers. YMI continues to grow its network of service centers worldwide and build on its enviable reputation as a complete systems provider and marine industry ambassador with new partnerships, co-operations and investment.

Based in the Netherlands, YMI is incorporated within Yanmar’s global operations, spanning seven business domains on land and at sea. With its beginnings in Osaka, Japan in 1912, Yanmar went on to become the first company to succeed in making a compact diesel engine of practical size in 1933. With industrial diesel engines as the cornerstone of the business, Yanmar has continued to expand its range of products, services and expertise to deliver total solutions as a diesel engine and equipment manufacturer, providing small and large engines, agricultural machinery and facilities, construction equipment, energy systems, marine engines, machine tools, and components.

About Yanmar America

Yanmar America Corporation, located in Adairsville, GA, is the regional headquarters of Yanmar Co., Ltd. a global company based in Osaka, Japan. Yanmar Co. Ltd., was established in 1912, and in 1933 became the world's first manufacturer to develop a practical small diesel engine. Today, Yanmar is a recognized leader in the design and manufacturing of advanced performance diesel engines and diesel-powered equipment, as well as gas engine-based energy systems. Yanmar America Corporation is located at 101 International Parkway, Adairsville, GA 30103. For more information, please visit yanmar.com/us.

- Note: Information contained in the news release is valid at the time of publication and may differ from the most recently available information.