Marine Commercial - Information

Yanmar to Expand Reconditioning Business Using Laser Cladding Technology

April 19, 2015

Yanmar Co., Ltd.

Yanmar Co., Ltd. is expanding its reconditioning business using laser cladding technology for marine and industrial engine parts.

Yanmar has purchased shares in Laser Cladding Singapore Pte. Ltd. (abbr. LCS), a company with a parts reconditioning business that spans from Asia to Europe. The purchase has been done through Yanmar Asia (Singapore) Corporation Pte. Ltd., one of Yanmar’s regional headquarter companies in Asia.

In addition, with a view to expanding laser cladding operations in Japan, LCS has established a wholly owned subsidiary, Laser Cladding Japan Co., Ltd. (abbr. LCJ).

Investment in LCS and Aim in Establishing LCJ:

Incorporating laser cladding for parts reconditioning into its diverse range of after services, is just another way Yanmar is ensuring our customers’ equipment is still reaping in profits long after the purchase. By doing so, parts that would normally be thrown away can continue to be used, minimizing impact on the environment. Moreover, with quicker parts supply machine downtime is minimized, and operation costs reduced.

LCJ Outline:

- Company Name: Laser Cladding Japan Co., Ltd.

- President: Yasufumi Ueyama

- Location: 1-1-1 Nagasu Higashidori, Amagasaki, Hyogo, Japan

- Operations: Reconditioning of parts for marine and industrial engines

- Established: April 6, 2015

- Capital: 50 million yen

Reference Data:

- Laser Cladding Technology for Reconditioning Parts

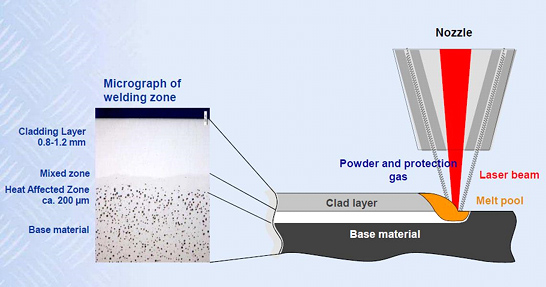

- Laser cladding enables parts that have eroded away to be put back into use. Metallic powder and shielding gas are blown into a focused laser spot as it is scanned across the target surface, leaving behind a deposited coating of the materials to restore the metal to previous or enhanced conditions, without the need to replace the part. The pond that is formed between substrate and the coating is a metallurgical bond and not a mechanical bond.

- Benefits of Reconditioning Using Laser Cladding

- Using a laser enables pin-point accuracy to the millimeter for the thickness of the deposited coating. This enables a laser cladded part to be near net shape and greatly reduces subsequent post-machining process time; it also reduces heat distortion into the part. By selecting optimal filler material, the cladding layer can provide added resistance to corrosion and wear and tear. As a result, this provides customers with more durability, cost savings and improves the engine life cycle value.

- Major Applications

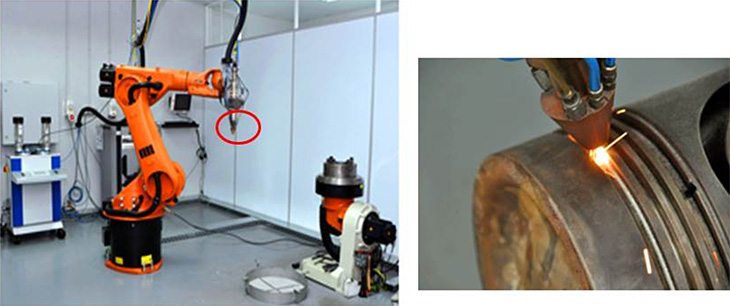

- Presently Yanmar is mainly applying this technology to pistons and parts for various shafts in internal-combustion engines.

- Note: Information contained in News Releases is valid at the time of publication and may differ from the most recently available information.