| Type | Zero Tail |

|---|---|

| Operating Weight | 4875 kg |

| Width | 1940 mm |

| Digging Depth | 3360 - 3610 mm |

The ViO50-6B is designed to provide true peace of mind, especially in urban environments where space is limited, and when working along walls. This zero tail swing machine also features a ViPPS hydraulic system for smooth, powerful performance. Numerous design features assist with easy maintenance, as does the optional SmartAssist Remote. All undercarriage components have been upgraded to further increase the durability of this rugged machine.

Specifications

| Specifications | ViO50-6B | |

|---|---|---|

| Weight | Transport weight | 5005 kg |

| Operating Weight | 4875 kg | |

| Engine | Type | 4TNV88C-PBV (Stage V engine with DPF) |

| Fuel | Diesel | |

| Net Power | 27.5 kW (at 2200 rpm) | |

| Gross Power | 28.3 kW (at 2200 rpm) | |

| Displacement | 2.189 l | |

| Max Torque | 133,3 - 144,9 N.m | |

| Starter | 12 V – 2.3 kW | |

| Battery | 12 V – 100 Ah | |

| Alternator | 12 V – 55 A | |

| Hydraulic System | Maximum Pressure | 245 bars |

| Working Pump | 2 double piston pump with variable flow / 1 gear pump / 1 gear pump for pilot line | |

| Max Flow | 2 x 42.5 l/min / 37 l/min / 10,8 l/min | |

| Hydraulic Tank | 38 l | |

| Performance | Travel speed | 2.4 – 4.6 km/h |

| Rotation Speed | 10 rpm | |

| Digging Force (arm) | 22.7 kN / 21.0 kN (with long arm) | |

| Digging Force (bucket) | 36.5 kN | |

| Traction Force | 42.7 kN | |

| Noise level (2000/14/CE & 2005/88/CE) | 80 dB(A) / 94 dB(A) | |

| Fuel Tank | 66 l | |

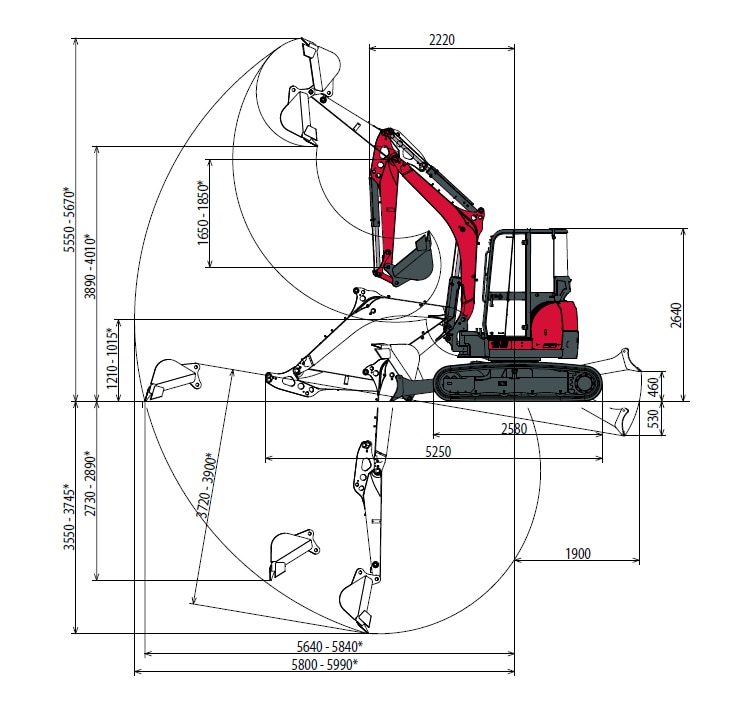

Dimensions

| Dimensions | ViO50-6B | |

|---|---|---|

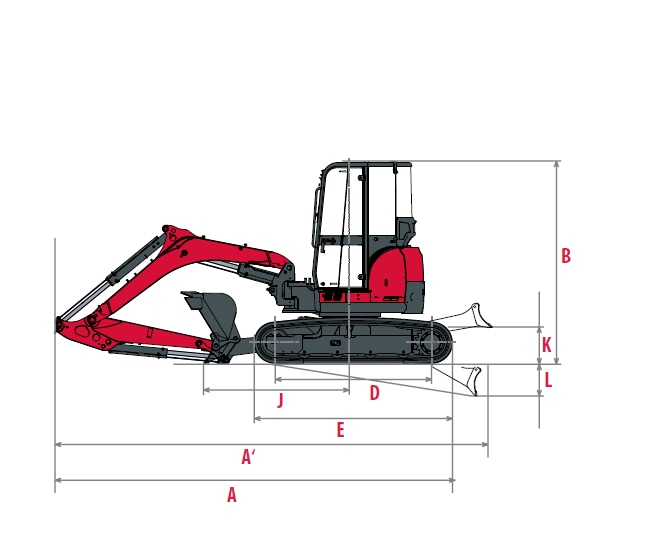

| A | Overall length | 5230 / 5330 * mm |

| B | Overall height | 2540 mm |

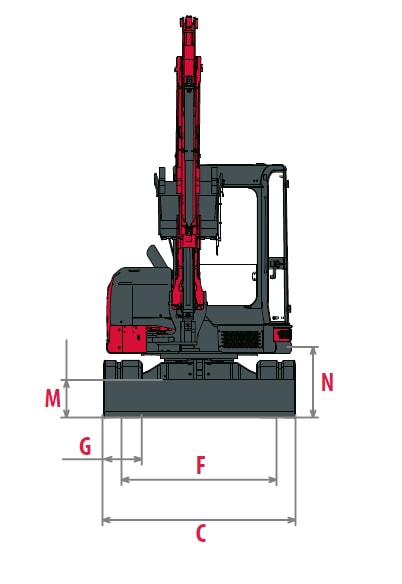

| C | Overall width | 1940 mm |

| D | Length of track on ground | 2070 mm |

| E | Undercarriage length | 2590 mm |

| F | Lane | 1590 mm |

| G | Track width | 350 mm |

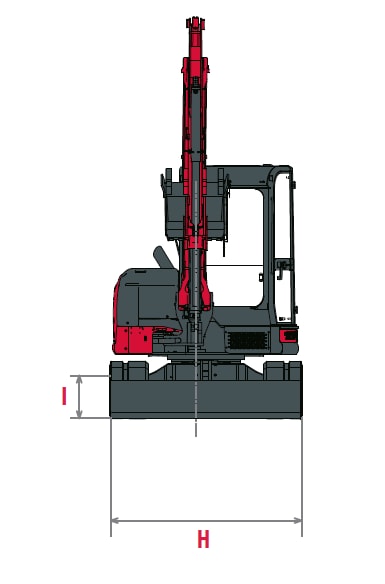

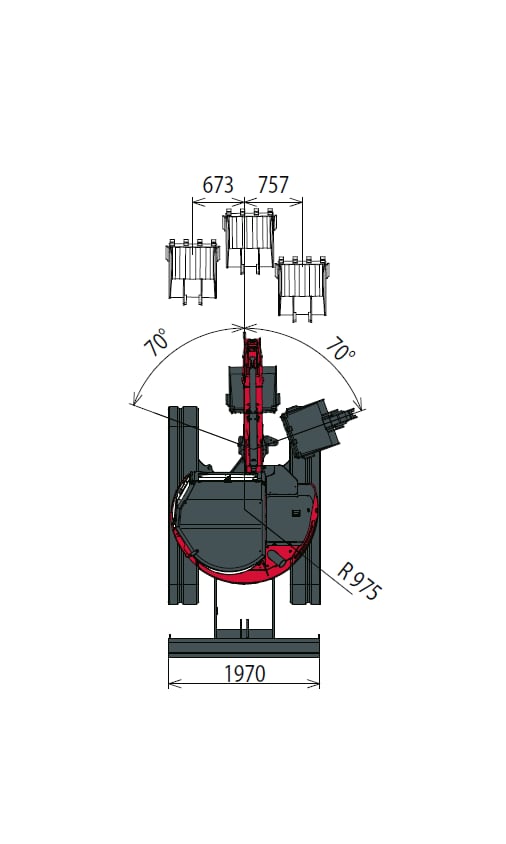

| H | Overall blade width | 1970 mm |

| I | Overall blade height | 400 mm |

| J | Blade distance | 1900 mm |

| K | Max. blade height above the ground | 510 mm |

| L | Max. lowering blade depth | 535 mm |

| M | Minimum ground clearance | 345 mm |

| Dimensions | ViO50-6B | |

|---|---|---|

| N | Max. digging depth - Blade lifted | 3360 / 3610 * mm |

| O | Max. digging depth - Blade lowered | 3540 / 3790 * mm |

| P | Max. digging reach on ground | 5540 / 5770 * mm |

| Q | Max. digging reach | 5700 / 5920 * mm |

| R | Max vertical wall | 2690 / 2880 * mm |

| S | Max. dumping height | 3870 / 4000 * mm |

| T | Max. cutting height | 5530 / 5650 * mm |

| U | Boom swinging base to left | 70° |

| V | Boom swinging base to right | 70° |

| W | Arm length | 1450 / 1700 * mm |

| X | Minimum front swing radius | 2185 / 2360 * mm |

| Y | Minimum front swing radius with boom swing | 1780 / 1910 mm |

| Z | Rear swing radius | 970 mm |

* With long arm

Features

COMPACTNESS

As a true zero tail swing machine, neither the counterweight nor the front part of the upper frame of the ViO50-6B project beyond the track width. This also means it has a very small turning radius. The rear blind spot has also been reduced to a minimum. These features all serve to improve safety for operators and other on-site workers alike. The design of the undercarriage helps reduce the machine height to just 2.54 m, which facilitates transportation of the machine. It also improves the ground clearance to 345 mm.

CLEAN STAGE V ENGINE

The advanced 28.3 kW TNV engine is equipped with direct injection to create clean burning power. The engine is also equipped with a common rail system to allow fine-tuned electronic control of fuel injection. The Yanmar engine is fully compliant with EU Stage V emission requirements, thanks to cooled exhaust gas recirculation (EGR) which drastically reduces nitrogen oxide emissions. In addition, the diesel particulate filter (DPF) helps clean up exhaust emissions. We have also developed an exclusive regeneration system to combat clogging and reduce cleaning down-time.

ELECTRONIC CONTROLS

Fully-electronic control provides intelligent power and manoeuvrability, with drive motors shifting automatically up and down depending upon the effort required. The operator is thus always provided with the best solution in terms of speed or pushing force, making operation easier. Eco-mode effectively controls the motor speed, which is reduced by 300 rpm, thereby reducing fuel consumption. If the operator doesn’t touch the operating levers for four seconds, the engine drops back to idle. This results in better fuel consumption and reduced noise and emissions.

SMOOTH AND SIMULTANEOUS MOVEMENT

The ViO50-6B uses a ViPPS hydraulic system consisting of one double variable displacement piston pump and two gear pumps. These three main pumps totalise a maximum flow of 132.8 l/min, available for main machine operating movements. Pump flows are cumulated in the main control valves to obtain the optimal combination of speed, power, smoothness and balance. The ViPPS system thus allows smooth and simultaneous performance of all operations, even when travelling.

ADVANCED COMFORT

The ergonomically designed cabin is luxurious and spacious, with a generous entrance and plenty of leg room. Welcome touches that help reduce operator fatigue include an adjustable wrist rest and a seat with pneumatic suspension. Three rear-view mirrors aid the excellent all-round visibility and promote safety. A translation lever with folding pedals also allows more operator space and therefore comfort, and all control levers are located for ease and precision of movement.

DURABILITY

All undercarriage components have been upgraded, which increases durability and reduces total cost of ownership. In particular, the X-shaped box-section structure of the undercarriage provides excellent torsional stiffness, while the frame is designed for maximum resilience. The box-like structure of the boom enhances the durability and service life of this component as well, and the boom’s base and swing post have been strengthened too. All cylinder tubes and rods in the boom are protected by a unique spring-type steel plate, which greatly aids durability.

EASY MAINTENANCE

The ViO50-6B is equipped with a digital interface which informs the operator in real time about the status of the machine and assists with servicing planning (although the machine can go a long time between services). Daily maintenance has additionally been made simple – there’s one easy-to-open engine bonnet and the right-hand side cover is mounted on one hinge to open easily too. This gives access to all major elements, such as the air filter, radiator, battery, fuel tank and much else. In addition, a flat floor mat makes cleaning easier.

Options

EQUIPMENTS

- Steel crawlers

- Rubber pads for steel crawlers YCE – warranty 12 months

- Long arm (+250mm)

- Proportional 3rd & 4th circuits with potentiometers

- Clamshell bucket circuit

- Hydraulic quick hitch line 150 – 165 bar

- Flat face hydraulic quick connectors on 3rd hydraulic circuit line

- Additional counterweight (+195 kg)

- Standard biodegradable oil

- 2 front LED working lights

- 1 rear LED work light + 1 LED flashing rotary

- 1 LED flashing rotary

- Beacon light with magnetic base

COMFORT

- Air conditioning

- Textile seat

- Radio

- Electric refuelling pump

- Documentation box

- Central greasing

SAFETY

- 3 safety valves with welded ring on the bucket link

- Lifting certificate (only for France)

- FOPS 1 protection

- Removable battery cut-off switch

- GPS trackunit ME501 standard

- Travel alarm

- Improved filtration (Turkey, Israel, Bulgaria, Romania, Ukraine, Slovakia and Russia)

- Special paint