| Type | Zero Tail |

|---|---|

| Operating Weight | 2770 kg |

| Width | 1500 mm |

| Digging Depth | 2490 - 2740 mm |

Truly exceptional performance and stability are what mark out the ViO27-6 as special, due to features such as its highly advanced engine, excellent weight distribution and zero tail status. It also offers superb precision, which is down to ergonomic controls and the ViPPS hydraulic system. Operator comfort and protection are also notable pluses, thanks to Yanmar Full Protect and thoughtful cabin design, while SmartAssist Remote is a further welcome boost to productivity.

Specifications

| Specifications | ViO27-6 | |

|---|---|---|

| Weight | Transport weight | 2590 kg (canopy) / 2695 kg (cabin) |

| Operating Weight | 2665 kg (canopy) / 2770 kg (cabin) | |

| Engine | Type | 3TNV76-NBVA1 |

| Fuel | Diesel | |

| Net Power | 15.2 kW / 20.7 HP at 2500 rpm | |

| Gross Power | 15.8 kW / 21.5 HP at 2500 rpm | |

| Displacement | 1.115 l | |

| Max Torque | 63.4-69,1 at 1800 rpm | |

| Starter | 12 V - 1.4 kW | |

| Battery | 12 V – 45 Ah | |

| Alternator | 12 V – 40 A | |

| Hydraulic System | Maximum Pressure | 210 bars |

| Working Pump | 2 double piston pump with variable flow / 1 gear pump / 1 gear pump for pilot line | |

| Max Flow | 2 x 30 l/min / 21,3 l/min / 11,3 l/min | |

| Hydraulic Tank | 25 l | |

| Performance | Travel speed | 2,8 / 4,5 km/h |

| Rotation Speed | 10 rpm | |

| Digging Force (arm) | 14.4 / 12.7 kN (with long arm) | |

| Digging Force (bucket) | 23,1 kN | |

| Traction Force | n/a | |

| Noise level (2000/14/CE & 2005/88/CE) | LWAG: 93 dBA; LPAG: 80 Dba | |

| Fuel Tank | 30,5 l | |

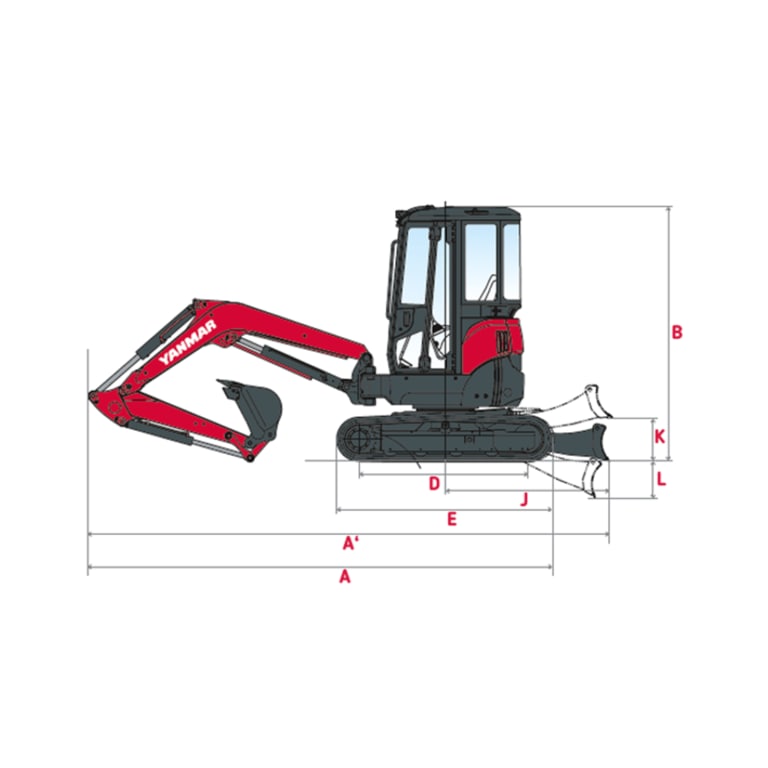

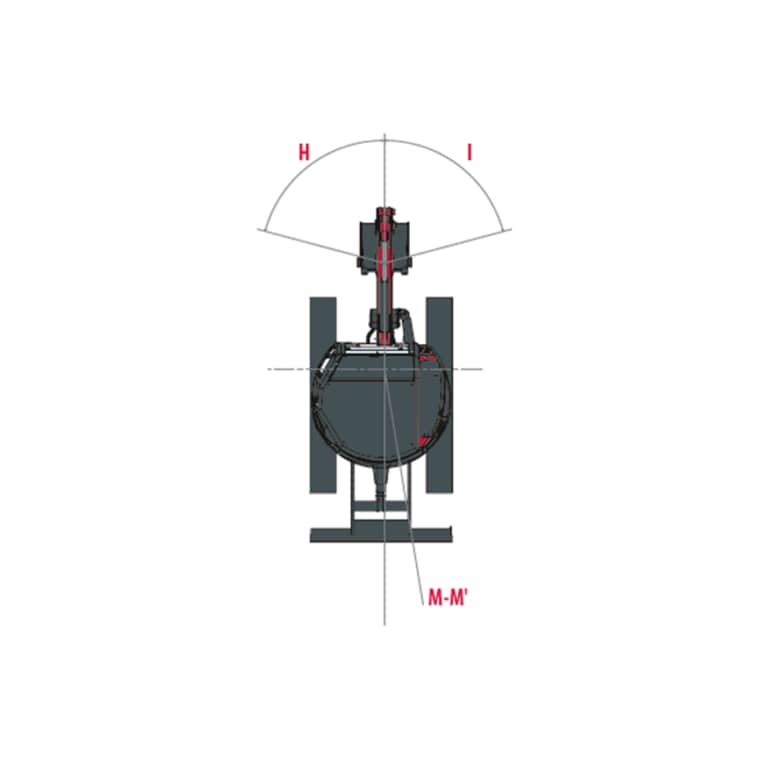

Dimensions

| Dimensions | ViO27-6 | |

|---|---|---|

| A | Overall length | 4110 / 4120 * mm |

| B | Overall height | 2530 mm |

| C | Overall width | 1500 mm |

| D | Length of track on ground | 1590 mm |

| E | Undercarriage length | 2040 mm |

| F | Lane | 1250 mm |

| G | Track width | 250 mm |

| H | Overall blade width | 1500 mm |

| I | Overall blade height | 290 mm |

| J | Blade distance | 1380 mm |

| K | Max. blade height above the ground | 340 mm |

| L | Max. lowering blade depth | 355 mm |

| M | Minimum ground clearance | 320 mm |

| Dimensions | ViO27-6 | |

|---|---|---|

| N | Max. digging depth - Blade lifted | 2490 / 2740 * mm |

| O | Max. digging depth - Blade lowered | 2690 / 2940 * mm |

| P | Max. digging reach on ground | 4340 / 4590 * mm |

| Q | Max. digging reach | 4460 / 4700 * mm |

| R | Max vertical wall | 1150 / 1290 * mm |

| S | Max. dumping height | 2830 / 2990 * mm |

| T | Max. cutting height | 3990 / 4140 * mm |

| U | Boom swinging base to left | 47° |

| V | Boom swinging base to right | 74° |

| W | Arm length | 1150 / 1400 * mm |

| X | Minimum front swing radius | 1950 / 1990 * mm |

| Y | Minimum front swing radius with boom swing | 1650 / 1680 * mm |

| Z | Rear swing radius | 750 mm |

* with long arm

Features

ZERO TAIL SWING

Operators can work with total peace of mind regarding the safety of those around them, especially in highly restricted urban environments, given that the ViO27-6 is a true zero tail mini-excavator. Since its front part does not protrude, it has a very small radius of rotation, allowing for safe upper frame rotation. Particularly efficient when walking along walls, dead angles are also reduced to a minimum, thanks to the excellent all-round visibility.

UNCOMPROMISED PERFORMANCE

The ViO27-6 offers exceptional performance for a machine in its class. Its digging depth of 2,940 mm with long arm and its digging forces (bucket) of 23.1 kN and digging forces (arm) of 14.4 kN allow it to work quickly and efficiently, even under severe conditions. The 1500 mm width of its undercarriage and excellent weight distribution offer similar or better stability compared to other machines of the same weight class, as well as great lifting capacities. An optional additional counterweight further enhances the stability of this excavator.

ELECTRONICALLY CONTROLLED MOTOR

With an output of 15.8 kW at 2,500 rpm, the advanced Yanmar engine is the result of our continuous efforts to achieve technological advances in fuel consumption and emissions. An improved fuel injection system further reduces emissions, as well as offering quieter operation. An auto-deceleration system lowers the engine speed to idle when the machine has not been used for more than four seconds and then automatically reaccelerates as soon as necessary, thereby also improving fuel economy.

SMOOTH AND SIMULTANEOUS MOVEMENT

The ViO27-6 features a ViPPS hydraulic system in a configuration that uses a double variable displacement piston pump and two gear pumps. These three key pumps totalise a maximum flow of 81.3 l/min, available for main machine operating movements. For an optimal combination of speed, power, smoothness and balance, the flows of these pumps are cumulated in the main control valves. The ViPPS system thus delivers smooth and co-ordinated performance across all operations, even while travelling, resulting in the ultimate working tool.

EASY OPERATION

All control levers on the ViO27-6 are ergonomically located in order to facilitate exceptional precision of movement. The standard equipment of the ViO27-6 includes an auxiliary hydraulic circuit which offers proportional control capability, located on the joystick. This adapts the quantity and the direction of the oil flow. In addition, the circuit has an optional easy-to-operate potentiometer which adjusts the oil flow to meet the optimal requirements of each attachment.

EXTRA COMFORT

The cabin is equipped as standard with a comfortable and ergonomic suspension seat with adjustable controls, high-backrest and retractable seatbelt. Spacious leg room is boosted by the flat floor, while all control levers are ideally located for exceptional ease and precision of movement, whether via joystick or foot pedal. The machine offers the operator an ergonomic environment, with excellent visibility and exceptional safety considerations. In particular, the cabin shape provides optimum 360° visibility to enhance on-site safety and improve efficiency.

YANMAR FULL PROTECT

The ViO27-6 benefits from the unique Yanmar Full Protect system. This provides complete protection of its boom and arm cylinders, with all cylinder tubes and rods safeguarded by a highly elastic steel plate. The result is significantly lower total cost of ownership of the machine. In addition, the cabin structure of the ViO27-6 has been designed to meet the requirements of ROPS certification, ensuing structural protection from rollovers, and Level 1 of FOPS certification, for protection from falling objects.

Options

EQUIPMENTS

- Steel crawlers (250mm)

- Long arm (+250mm)

- Proportional 3rd & 4th circuits with potentiometers

- Clamshell bucket circuit (not compatible with 4th hydr. circuit)

- Hydraulic quick hitch line

- Flat face hydraulic quick connectors 3rd circuit

- Additional counterweight (+90 kg)

- Standard biodegradable oil

- 2 front LED working lights

- 1 rear LED work light + 1 LED flashing rotary

- 1 LED flashing rotary

- Beacon light with magnetic base

COMFORT

- Vinyl seat premium

- Radio

- Documentation box

SAFETY

- 3 safety valves with welded ring on the bucket link

- Removable battery cut-off switch (steel)

- Travel alarm

- Special paint