| Type | Conventional Tail |

|---|---|

| Operating Weight | 8200 kg |

| Width | 2270 mm |

| Digging Depth | 4180 mm |

Ultra-tight turning, exceptional flexibility and unmatched compactness make this machine the right choice for densely populated areas and restricted urban sites. A unique three-piece boom offers the best dumping and digging heights in its class, together with exceptional stability. The powerful 53.5 kW TNV engine comes with electronic controls and offers exceptional performance and fuel economy. Operators also benefit from a spacious, ergonomically designed cabin, with many luxury touches fitted as standard.

Specifications

| Specifications | B7-6 | |

|---|---|---|

| Weight | Transport weight | 8125 kg |

| Operating Weight | 8200 kg | |

| Engine | Type | 4TNV98C-WBV2 |

| Fuel | Diesel | |

| Net Power | 39,3 kW (at 1900 rpm) | |

| Gross Power | 41,4 kW (at 1900 rpm) | |

| Displacement | 3.318 l | |

| Max Torque | 229 ~ 241 N.m | |

| Starter | 3 kW | |

| Battery | 12V - 92 Ah | |

| Alternator | 12V - 80 A | |

| Hydraulic System | Maximum Pressure | 255 bars |

| Working Pump | 2 double piston pump with variable flow / 1 gear pump / 1 gear pump for pilot line | |

| Max Flow | 2 x 70,3 l/min / 59,8 l/min / 19 l/min | |

| Hydraulic Tank | 60 l | |

| Performance | Travel speed | 2,7 / 4,8 km/h (2,5 / 4,5 km/h with steel tracks) |

| Rotation Speed | 10 rpm | |

| Digging Force (arm) | 40,6 kN | |

| Digging Force (bucket) | 56,9 kN | |

| Traction Force | 72,6 kN | |

| Noise level (2000/14/CE & 2005/88/CE) | 80 dB(A) (LpA) / 97 dB(A) (LwA) | |

| Fuel Tank | 115 l | |

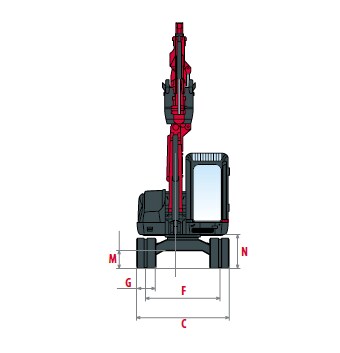

Dimensions

| Dimensions | B7-6 | |

|---|---|---|

| A | Overall length | 5850 mm |

| B | Overall height | 2680 mm |

| C | Overall width | 2270 mm |

| D | Length of track on ground | 2290 mm |

| E | Undercarriage length | 2890 mm |

| F | Lane | 1870 mm |

| G | Track width | 450 mm |

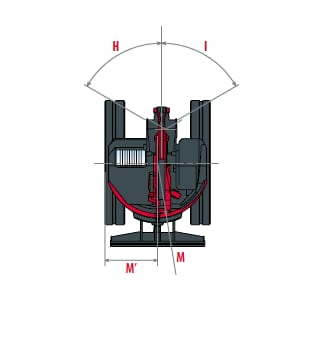

| H | Overall blade width | 2270 mm |

| I | Overall blade height | 435 mm |

| J | Blade distance | 1830 mm |

| K | Max. blade height above the ground | 440 mm |

| L | Max. lowering blade depth | 380 mm |

| M | Minimum ground clearance | 390 mm |

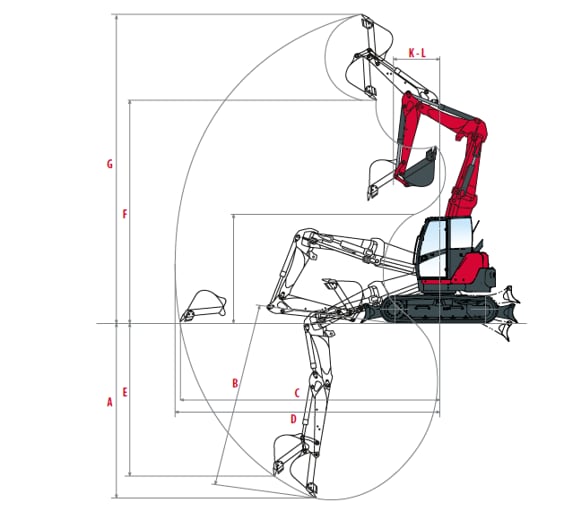

| Dimensions | B7-6 | |

|---|---|---|

| N | Max. digging depth - Blade lifted | 4180 mm |

| O | Max. digging depth - Blade lowered | 4450 mm |

| P | Max. digging reach on ground | 6370 mm |

| Q | Max. digging reach | 6520 mm |

| R | Max vertical wall | 3690 mm |

| S | Max. dumping height | 5540 mm |

| T | Max. cutting height | 7530 mm |

| U | Boom swinging base to left | 1060 mm |

| V | Boom swinging base to right | 870 mm |

| W | Arm length | 1680 mm |

| X | Minimum front swing radius | 1320 mm |

| Y | Minimum front swing radius with boom swing | 1139 mm |

| Z | Rear swing radius | 1265 mm |

Subject to technical modifications. Dimensions in mm with specific Yanmar bucket.

Features

COMPACTNESS

The B7∑-6 is the most compact excavator in the 8-10 ton class and is a true zero tail swing machine. It has a complete swing radius of 1,320 mm, which is 34% less than comparable machines with an articulated boom. Its transport dimensions are just 5,850 mm x 2,270 mm x 2,680 mm and it’s so compact that the operator can perform a complete 360° turn in a traffic lane just 2.7 meters wide, helping to reduce traffic congestion. This makes it an ideal choice for jobsites in densely populated areas and urban sites with limited space.

UNIQUE BOOM CONCEPT

The Yanmar Sigma boom is a three-piece offset device which offers the smallest turning radius, an increased lifting performance, and optimal visibility across the working zone for the operator. The Sigma boom has several other big advantages as well, offering the best dumping height and digging height combination in its class, combined with extraordinary digging depth. When working in narrow trenches with the boom offset, the second part of the boom does not strike the left-hand shoring plate, as tends to occur with traditional excavators.

FLEXIBILITY AND PRODUCTIVITY

Even with an attachment fitted, the dipper stick can easily manoeuvre around or get under an obstacle, thanks to the overall flexibility that’s at the heart of the design of this machine. The second articulation of the boom provides the offset on lateral movement of the workgroup and attachment without having to rotate the upper frame. This offers enormous gains in both productivity and visibility for the operator.

EXCELLENT STABILITY

The B7∑-6 has exceptional stability due to its unique boom design, since the pivot point of the boom is located close to the centre of gravity of the machine. This makes this machine the optimal tool for lifting and placing loads in high-level situations. In addition, it’s equipped with the patented VICTAS system. This unique track design is the key to an offset rolling path that enables the excavator to lift challenging loads with increased performance, while still being the most compact machine in its class.

POWERFUL ECO-FRIENDLY ENGINE

The advanced 53.5 kW TNV engine developed by Yanmar meets all EU Stage V emission requirements, thanks to cooled exhaust gas recirculation (EGR) which drastically reduces nitrogen oxide emissions, and a diesel particulate filter (DPF) that ensures cleaner exhaust emissions. Other eco-friendly features include direct injection for cleaner burning power, with a common rail system that delivers fine-tuned control. In addition, an exclusive regeneration system combats clogging and reduces cleaning down-time.

ELECTRONIC ENGINE CONTROLS

Full electronic control gives the engine intelligent power and manoeuvrability, with drive motors automatically shifting up or down depending upon the effort required. This provides the operator with the best solution in terms of speed or pushing force, making operation easier. The eco-mode function reduces motor speed by 300 rpm, thereby reducing fuel consumption. If the operator doesn’t touch the operating levers for four seconds, the engine drops back to idle, further saving fuel, while also resulting in less noise and fewer emissions.

SMOOTH CONTROL

The machine is equipped with a ViPPS hydraulic circuit with aggregated power regulation from three variable flow piston pumps and a multiple combination directional control valve. The pumps engage automatically depending on the operation being performed, providing greater ease of use for the operator. The combination of the pump flows helps increase work speed while also ensuring smooth and simultaneous performance across all operations, even while the B7∑-6 is travelling.

SPACIOUS AND COMFORTABLE CABIN

A lot of thought has gone into the operator station to ensure both greater comfort and productivity. Both the width and the length of the cabin have been increased to deliver an exceptionally roomy interior, while the noise levels inside are surprisingly low. The air suspension seat is standard and can be adjusted in multiple ways by itself, or simultaneously with the consoles, a feature normally found only in large excavators. This allows the operator easily to find their optimal working position. Other pluses include air conditioning, secure document storage, and a radio with USB port.

EASY MAINTENANCE

For daily maintenance, there’s an easy-to-open engine bonnet, with the right-hand side cover mounted on one hinge for quick opening. This allows access to all major elements, including the air filter, radiator, refuelling pump, battery, fuel tank, hydraulic oil tank and so on. The fuses and relays are located under the seat and are thus easily accessible. The diesel particulate filter (DPF) and diesel oxidation catalyst (DOC) are both maintenance-free, while the soot filter (SF) only needs to be cleaned after every 3,000 hours of use.

Options

EQUIPMENTS

- Steel crawlers

- Rubber pads for steel crawlers YCE – warranty 12 months

- Clamshell bucket circuit

- Additional counterweight (+400 kg)

- Hydraulic quick hitch line 150 -165 bar

- Flat face hydraulic quick connectors

- Standard biodegradable oil

- 1 rear LED work light + 1 LED flashing rotary

- 1 LED flashing rotary

- Beacon light with magnetic base

COMFORT

- Vinyl seat

- Central greasing

- Lifting certificate

SAFETY

- FOPS 2 protection (front + top guard)

- Removable battery cut-off switch

- Special paint

Attachments

Media

B7 Sigma-6