| Type | Zero Tail |

|---|---|

| Operating Weight | 1245 kg |

| Width | 830 - 1000 mm |

| Digging Depth | 1950 mm |

High performance with low fuel consumption is just one of the many advantages of the ViO12-2A. It’s also been designed to be easy and comfortable to use, and just as simple to maintain. Extendable undercarriage makes it a zero-tail machine, as delivering extra stability and greater lifting capabilities. A monoblock chassis also adds to its robustness and stability. Longer tracks, durable parts and axial piston pumps all see it outscore the competition.

Specifications

| Specifications | ViO12-2A | |

|---|---|---|

| Weight | Transport weight | 1170 kg |

| Operating Weight | 1245 kg | |

| Engine | Type | 3TNV70-WBVB |

| Fuel | Diesel | |

| Net Power | 9,2 kW / 12,5 HP / 2 000 rpm | |

| Gross Power | 9,3 kW / 12,6 HP / 2 000 rpm | |

| Displacement | 0.854 l | |

| Max Torque | 48,1 ~ 52 Nm / 1 500 rpm | |

| Starter | 12V - 1.1 kW | |

| Battery | 12V - 36 Ah | |

| Alternator | 14V - 8.5A | |

| Hydraulic System | Maximum Pressure | 210 bars |

| Working Pump | 1 double piston pump with variable flow | |

| Max Flow | 2 x 11 l/min | |

| Hydraulic Tank | 7,4 l | |

| Performance | Travel speed | 2,1 - 4 km/h |

| Rotation Speed | 10 rpm | |

| Digging Force (arm) | 5,68 kN | |

| Digging Force (bucket) | 13,63 kN | |

| Traction Force | n/a | |

| Noise level (2000/14/CE & 2005/88/CE) | 88 dBA | |

| Fuel Tank | 12 l | |

Dimensions

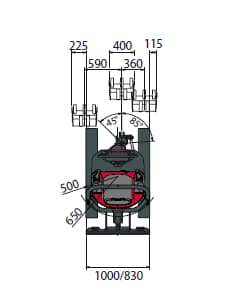

| Dimensions | ViO12-2A | |

|---|---|---|

| A | Overall length | 3040 mm |

| B | Overall height | 2250 mm |

| C | Overall width | 830 / 1000 * mm |

| D | Length of track on ground | 1095 mm |

| E | Undercarriage length | 1440 mm |

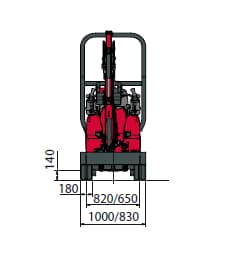

| F | Lane | 820 / 650 mm |

| G | Track width | 180 mm |

| H | Overall blade width | 830 / 1000 * mm |

| I | Overall blade height | 219 mm |

| J | Blade distance | 930 mm |

| K | Max. blade height above the ground | 210 mm |

| L | Max. lowering blade depth | 230 mm |

| M | Minimum ground clearance | 140 mm |

| Dimensions | ViO12-2A | |

|---|---|---|

| N | Max. digging depth - Blade lifted | 1950 mm |

| O | Max. digging depth - Blade lowered | 2050 mm |

| P | Max. digging reach on ground | 3270 mm |

| Q | Max. digging reach | 3350 mm |

| R | Max vertical wall | 1650 mm |

| S | Max. dumping height | 2370 mm |

| T | Max. cutting height | 3150 mm |

| U | Boom swinging base to left | 50° |

| V | Boom swinging base to right | 90° |

| W | Arm length | 830 mm |

| X | Minimum front swing radius | 1330 mm |

| Y | Minimum front swing radius with boom swing | 1080 mm |

| Z | Rear swing radius | 650 mm |

*Undercarriage extended – retracted

Subject to any technical modifications. Dimensions given in mm with standard Yanmar bucket.

Features

EXTENDABLE UNDERCARRIAGE

The undercarriage extends to 1,000 mm, offering extra frontal stability and smoother operation, as well as more powerful lifting capabilities. Retracted, it measures just 830 mm, reducing width and increasing manoeuvrability. The blade can be quickly and easily extended, safeguarding extensions. The one-piece monoblock chassis adds extra robustness and also acts as a powerful counterweight for when the machine is revolving through 360 degrees. At 1,440 mm, the tracks are longer than other models in its class as well.

COMPACTNESS

The ViO12-2A is a true zero-tail machine – with the undercarriage extended, neither the counterweight nor the front part of the upper frame exceed the width of the crawlers. This makes it safer, more versatile, and easy to use in confined areas. Even when retracted, the rear of the machine only overlaps by 85 mm. With the boom swing, the front swing radius is 1080 mm, while the rear swing radius is only 650 mm – a real plus in confined spaces. The longer tracks also improve stability and deliver a smoother ride.

HIGH PERFORMANCE

The three-cylinder engine is pleasantly quiet and offers low fuel consumption. Together with the advanced cooling system it delivers excellent hydraulic performance without overheating, even in hot climates. It matches the competition for break-out force (13,9 kN) and tear-out force (5,8 kN), while its digging depth of 1,950 mm is markedly superior. Thanks to its two variable flow pumps, it’s capable of working with a breaker without interruption. By using axial piston pumps it also copes with working pressure better than competitors’ machines. A second travel speed switch is available as standard, allowing speeds of up to 4 km/h.

EASE OF USE

Ergonomically designed, the seat position of the operator has been carefully thought out for maximum comfort while ensuing everything is within easy reach for effortless operation. To aid this, there are precision joysticks located on both sides of the seat. This makes it easier to control all movements of the machine, while remaining comfortable to use at all times. As a result, both precision and overall productivity are increased.

EASY MAINTENANCE

The ViO12-2A has been designed for easy maintenance and service, thereby reducing downtime and extending working life. Serviceable parts can be reached quickly and easily. For example, the frontal hydraulic distributor has immediate access, while the large bonnet makes engine servicing easier. The hydraulic pipes on the back of the arm can also be accessed directly and, as they are in several sections, only the affected part needs replacement if there’s a breakage. We use very few plastic working parts compared to our competitors, which results in greater durability and the highest residual value in its class.

Options

- Flat face hydraulic quick connectors

- Standard biodegradable oil

- Seat raiser

- Documentation box

- Valve for return to tank

- Removable battery cut-off switch

- Travel alarm

- Special paint