| Type | Conventional Tail |

|---|---|

| Operating Weight | 5655 - 5685 kg |

| Width | 1990 mm |

| Digging Depth | 3650 - 3945 mm |

A winning combination of technology and innovation, the SV60-6B offers the performance of a midi excavator while reaping the benefits of a compact excavator. Designed to work effectively on a wide variety of sites, it combines compactness, power, versatility, reliability and durability. Featuring numerous design touches for operator safety and comfort, advanced standard equipment includes a rear-view camera, a progressive ViPPS hydraulic system, an adjustable air-suspended seat, and automatic two-speed drive motors.

Specifications

| Specifications | SV60-6B | |

|---|---|---|

| Weight | Transport weight | 5580 kg |

| Operating Weight | 5655 kg | |

| Engine | Type | Engine EU Stage V with Diesel Particulate Filter (DPF) |

| Fuel | Diesel | |

| Net Power | 33,5 kW (at 2 200 rpm) | |

| Gross Power | 34,5 kW (at 2 200 rpm) | |

| Displacement | 2.091 l | |

| Max Torque | 162,4 - 176.6 N.m | |

| Starter | 12 V - 2.3 kW | |

| Battery | 12 V – 100 Ah | |

| Alternator | 12 V – 80 A | |

| Hydraulic System | Maximum Pressure | 245 bars |

| Working Pump | 1 double piston pump with variable flow / 1 gear pump / 1 gear pump for pilot line | |

| Max Flow | 2 x 45.8 l/min / 37 l/min / 10.8 l/min | |

| Hydraulic Tank | 38 l | |

| Performance | Travel speed | 2.2 / 4.7 km/h |

| Rotation Speed | 10 rpm | |

| Digging Force (arm) | 24.8 / 27.3 kN (with long arm) | |

| Digging Force (bucket) | 41.9 kN | |

| Traction Force | n/a | |

| Noise level (2000/14/CE & 2005/88/CE) | Lwag: 95 dBA ; Lpag: 79 dBA | |

| Fuel Tank | 100 l | |

Dimensions

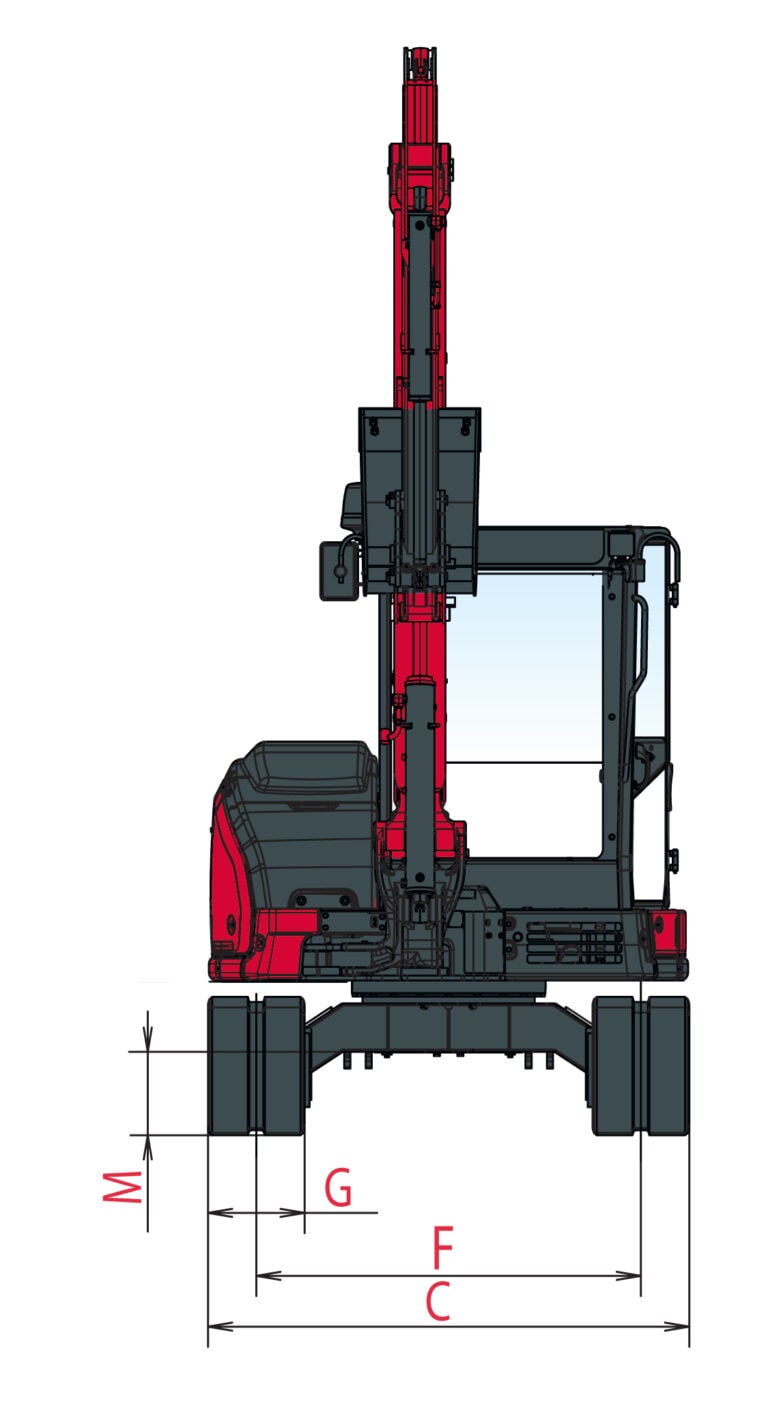

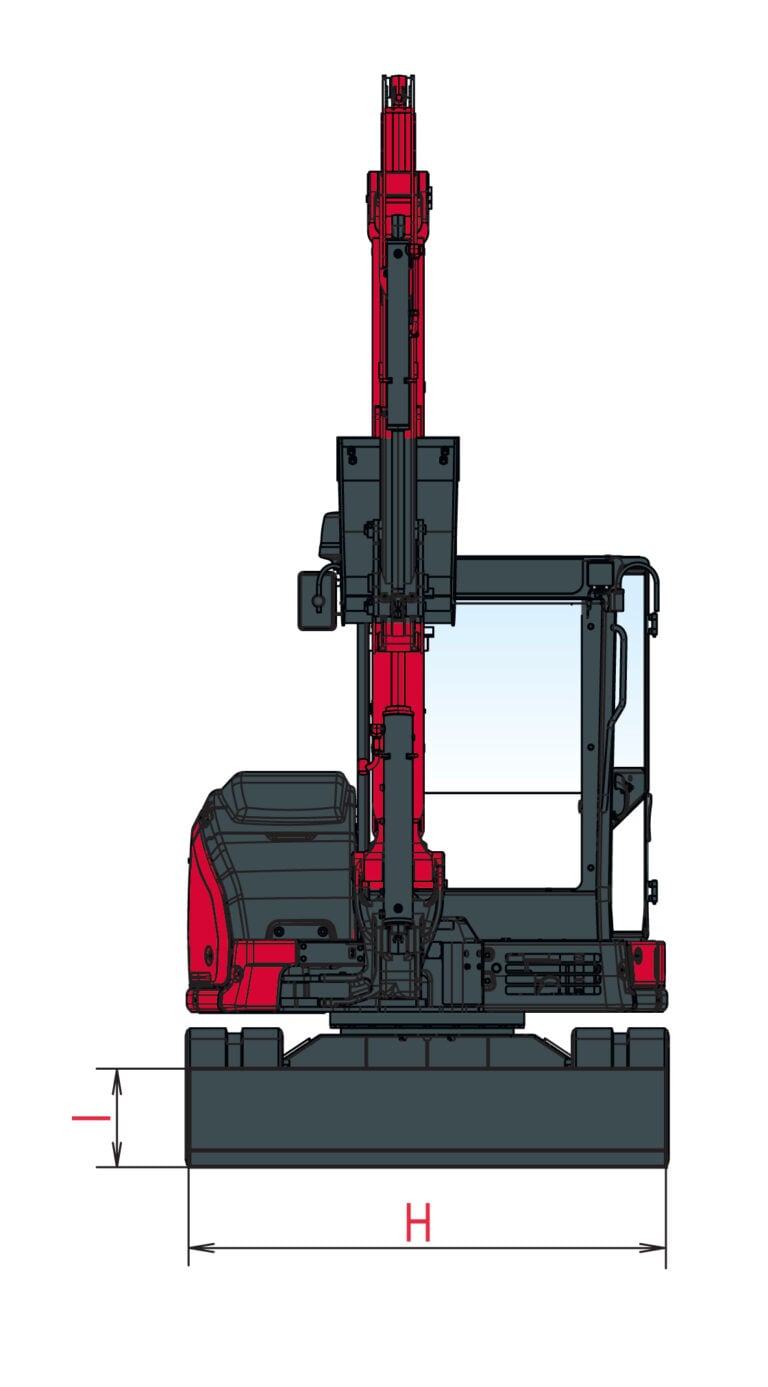

| Dimensions | SV60-6B | |

|---|---|---|

| A | Overall length | 5 595 / 5 675 * mm |

| B | Overall height | 2 540 mm |

| C | Overall width | 1 990 mm |

| D | Length of track on ground | 2 070 mm |

| E | Undercarriage length | 2 500 mm |

| F | Lane | 1 590 mm |

| G | Track width | 400 mm |

| H | Overall blade width | 1 970 mm |

| I | Overall blade height | 400 mm |

| J | Blade distance | 1 890 mm |

| K | Max. blade height above the ground | 510 mm |

| L | Max. lowering blade depth | 535 mm |

| M | Minimum ground clearance | 345 mm |

| Dimensions | SV60-6B | |

|---|---|---|

| N | Max. digging depth - Blade lifted | 3 650 / 3 945 * mm |

| O | Max. digging depth - Blade lowered | 3 910 / 4 200 * mm |

| P | Max. digging reach on ground | 5 990 / 6 265 * mm |

| Q | Max. digging reach | 6 135 / 6 410 * mm |

| R | Max vertical wall | 1 165 mm |

| S | Max. dumping height | 4 280 / 4 460 * mm |

| T | Max. cutting height | 5 720 / 5 900 * mm |

| U | Boom swinging base to left | 70° |

| V | Boom swinging base to right | 70° |

| W | Arm length | 1 650 / 1 940 * mm |

| X | Minimum front swing radius | 2 240 mm |

| Y | Minimum front swing radius with boom swing | 1 840 mm |

| Z | Rear swing radius | 1 325 mm |

* with long arm

Features

URBAN POWERHOUSE

The SV60-6B is designed for a wide range of applications such as urban renewal, grading or landscaping. With a very short rear overhang and a minimal front turning radius of only 2,240 mm, it’s particularly suitable for tasks in built-up areas that require a more powerful machine, but with no need for blocking off additional traffic lanes. Thanks to its unique design, this 5.6 tonne model has a very compact working envelope of only 3,565 mm.

BUSINESS CLASS CABIN

The SV60-6B is a prime example of how Yanmar Universal Design puts ergonomics and operator comfort at the heart of the machine. Cabin volume is comparable to that of a much larger excavator, with plenty of leg room. All controls are easily accessible and grouped on the right side, while the pedals are foldable for extra space. An adjustable air-suspended seat with headrest as standard offers optimal comfort for a machine of this weight class. Luxury touches include cup and bottle holder, utility box, phone tray, document storage and even a dedicated place for a lunchbox behind the seat.

CLEAN STAGE V ENGINE

The Yanmar engine meets all EU Stage V emission requirements. This is thanks to cooled exhaust gas recirculation (EGR) which dramatically reduces nitrogen oxide emissions and a diesel particulate filter (DPF) that helps clean up exhaust emissions. We have also developed an exclusive regeneration system to combat clogging and reduce time required for servicing. In addition, the advanced 28.3 kW TNV engine is equipped with direct injection to create clean burning power, plus a common rail system to allow fine-tuned electronic control of fuel injection.

ELECTRONIC CONTROLS

Fully-electronic control gives the operator intelligent power and manoeuvrability, with automatic provision of the optimum solution in terms of speed or pushing force. This is thanks to drive motors that automatically shift up or down depending upon what’s required. Eco-mode reduces motor speed by 300 rpm, thereby reducing fuel consumption. If the operator doesn’t touch the operating levers for four seconds, the engine drops back to idle. This also results in better fuel economy, along with reduced noise and emissions.

SMOOTH AND SIMULTANEOUS MOVEMENT

The SV60-6B is equipped with a progressive ViPPS hydraulic system that features three types of pumps – four hydraulic pumps, two variable displacement pumps and two gear pumps (including one for joysticks). Between them, they deliver a total flow of as much as 139.4 l/min. Completing the system is a control valve based on the ViPPS principle, which cumulates the flow of the separate pumps in order to obtain the optimal combination of speed, power, smoothness and balance. The system thus ensures smooth and seamless performance at all times, even when travelling.

EASY TO USE

An auxiliary hydraulic circuit operates via a proportional control function located on the joystick which adapts the supply and direction of the oil flow. The circuit also has an easy-to-operate potentiometer which adjusts the flow to the optimal requirement for each attachment. A drive motor develops 10% more torque, improving cycle times and productivity, especially in levelling applications. Other standard equipment includes new two-speed drive motors which automatically shift up or down, depending upon the effort required. This gives the operator the best solution in terms of speed or pushing force, without the need for any effort on their part.

MAXIMUM STABILITY

The SV60-6B benefits from an undercarriage with a unique design featuring a large counterweight and excellent weight distribution. This delivers unmatched stability for this weight class, together with remarkable lifting capabilities. The machine is capable of carrying loads of one at a height of 1.25 m for up to 5.10 m. An optional additional counterweight adds a further 200 kg and improves the lifting performance of the machine still further.

HIGH RELIABILITY

The X-shaped box-section structure of the undercarriage provides excellent torsional stiffness. Together with the steel covers, it provides optimal protection and longer service life. In addition, a lot of thought has gone into the hose routing on the working equipment. The SV60-6B also benefits from unique and comprehensive protection of all its cylinders, with all tubes and rods protected by a spring type steel plate. Features such as these reduce downtime and dramatically reduce the total cost of ownership of the machine.

OPTIMAL SAFETY

Standard equipment includes a rear-view camera with a wide LCD 7’’ screen to enhance on-site safety and make the operator’s job easier. Waterproof, it also offers night vision and has integrated heating for durability. Easy to use, it has many different settings, a mirror mode and even the option of connecting a second side camera. In addition, the SV60-6B’s design provides an ergonomic environment, including the largest cabin entrance on the market. Excellent visibility and exceptional safety features include three mirrors, plus a roof window for total visibility during loading and unloading.

EASY ACCESS

The SV60 is designed for maximum up-time, with service levels kept to a minimum and with day-to-day maintenance quick and easy to perform. To facilitate this, the main bonnet has a wide opening, enabling easy access to all major elements that may require attention. These include the air filter, compressor, battery, fuses and relays, the fuel tank, the hydraulic oil tank and the engine oil dipstick. Overall, there are five separate hoods or openings to allow easy access for component maintenance.

Options

EQUIPMENTS

- Steel crawlers

- Rubber pads for steel crawlers YCE

- Long arm (+290mm)

- Proportional 3rd & 4th circuits with potentiometers

- Clamshell bucket circuit

- Hydraulic quick hitch line 150 – 165 bar

- Flat face hydraulic quick connectors on 3rd hydraulic circuit line

- Additional counterweight (+200 kg)

- Standard biodegradable oil

- 2 front LED working lights

- 1 rear LED work light + 1 LED flashing rotary

- 1 LED flashing rotary

- Beacon light with magnetic base

- Air conditioning

COMFORT

- Vinyl seat

- Radio

- Documentation box

- Central greasing

SAFETY

- 3 safety valves with welded ring on the bucket link

- FOPS 2 protection (front + top guard)

- Removable battery cut-off switch (steel)

- Travel alarm

- Special paint

Attachments

Media

SV60, the perfect combination between performance, comfort, compactness, stability and versatility.

Business Class