Driving Sustainability with the Farm Circular Solution

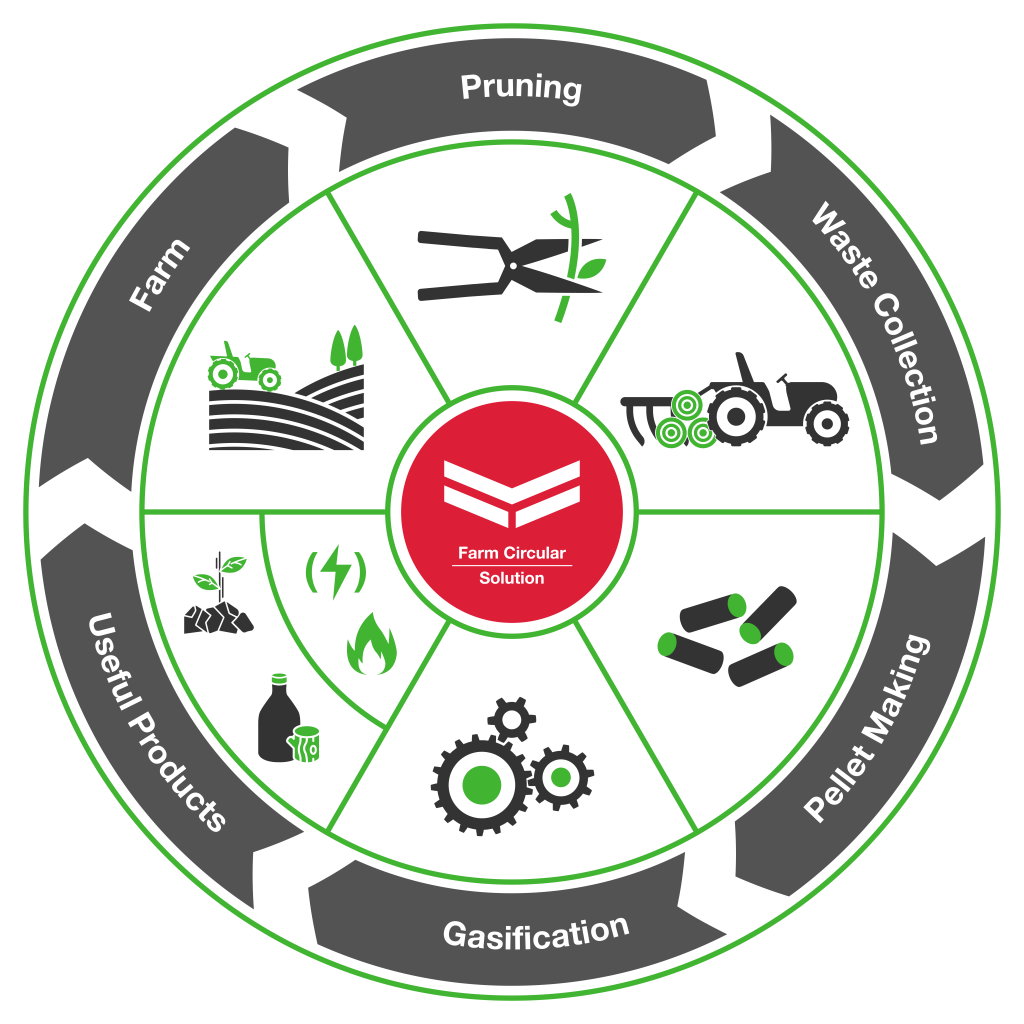

Yanmar’s Farm Circular Solution (FCS) is a highly portable containerized solution that turns farm waste into energy and useful agricultural products. By creating a sustainable cycle, the project reduces waste and contributes to more environmentally friendly farming.

Researchers at Yanmar R&D Europe have paired an efficient Yanmar combined heat and power (CHP) generator with advanced gasifier technology to deliver a solution that solves the challenge of farm waste. Farmers simply feed woody farm waste in one end, to produce power, heat, and useful farm products. The whole system is portable and fits neatly in two standard sized shipping containers.

A Sustainable Cycle

Waste disposal on farms comes with significant environmental concerns, including air quality, disposal costs and biological hazards associated with rotting vegetation, while government regulations also limit the allowed period of burning. Instead of burning agricultural residue, Yanmar technology allows farmers to convert it into useful products such as electricity, heat, biochar and wood vinegar. This project is valuable for any farm with woody agricultural residues from permanent crops such as olive groves, vineyards and orchards.

Roberto Mussi is Group Leader of the Renewable Energy Group at Yanmar Research & Development Europe (YRE) in Florence:

The advantages of FCS derive from its circularity. Farm waste is usually burned, but thanks to Yanmar technology, the waste is used to create useful products.

This circular loop created by converting waste helps improve the overall sustainability of the farm and reduces its environmental impact.

Developing Renewable Energy through Agricultural Waste

Valerio Magalotti, Senior researcher specializing in Design & Testing at YRE, played a key role in developing the technical process which enables the conversion of agricultural waste into useful energy and farm products. The process begins by collecting the farm waste and forming it into bails, then transforming and processing them into pellets. These pellets are fed into a gasification unit that produces a combustible “syngas” which powers the generator, a Yanmar clean diesel engine modified to run on syngas. The system produces an output of 20 kW electric and 35kWth heat providing an environmentally sustainable solution for powering farms and reducing operating costs.

Two more valuable by-products of the gasification process are being evaluated: biochar and wood vinegar. Biochar is a type of charcoal produced from plant matter. By using it as a soil substrate that supports plant growth, the carbon in the biochar is permanently removed from the atmosphere. Wood vinegar is another by-product of FCS. It is a natural pesticide which stimulates plant growth and improves soil conditions. Both products offer impressive environmental benefits and contribute to a more positive and sustainable farm ecosystem.

Yanmar Technology for Cleaner Fuel

For Lorenzo Pezzola, Senior Researcher at YRE, one of the key benefits of FCS is that it produces more than one valuable product. To make the most of this, Lorenzo says that one of his most important tasks is to define a wellbalanced system to ensure optimal quality for each of these products.

Another challenge the team has had to address is gas quality, which can be reduced by the presence of contaminants. The team came up with an innovative solution in the form of a multi-stage, self-cleaning catalytic filter. In Lorenzo’s words:

This helps us obtain the maximum quality of gas, which means maximum value for the customer.

Environmental Benefits to Farms

The introduction of the Farm Circular Solution has already benefitted Yanmar’s customers. Filippo Legnaioli is the president of a consortium of 185 farms in the area around Florence. He started collaborating with Yanmar a year ago and has noticed two key advantages of FCS to his farms in terms of environmental sustainability.

The first is the reduced impact of chemical fertilisers in his fields through the use of wood vinegar and biochar. He dedicated part of his field to Yanmar testing and sprayed wood vinegar on his olive trees 4-5 times during the summer, noticing that the disruption usually caused by the olive fruit fly (Bactrocera oleae) was significantly reduced.

The second benefit is reduced energy consumption. The olive farming consortium owns an olive mill in San Casciano in Val di pesa, just outside Florence. Approximately 10 of the consortium’s farms bring their waste to the olive mill where the Farm Circular System is installed. The olive oil mill has reduced its energy consumption by using the energy produced by the gasifier from these farms’ agricultural waste. Legnaioli sums up the impact of FCS on his business’s sustainability: “It’s a very good result for our farmers, and for me.”

Lasting Impacts in Agriculture and Beyond

As Group Leader of the Renewable Energy Group at Yanmar R&D Europe, Roberto is optimistic about the future of the FCS and believes its role as a decentralized energy solution will be key in bringing about increased energy sustainability on farms. Furthermore, the new technology’s replicability elsewhere means Roberto is confident FCS can continue to offer sustainable solutions to farms and beyond.

The Farm Circular Solution aligns with the Yanmar Green Challenge 2050, aiming to transform Yanmar into an environmentally friendly, greenhouse gas-free company. The Yanmar Green Challenge 2050 is part of Yanmar’s effort to tackle the challenges facing society towards the realization of the company’s Brand Statement: A Sustainable Future.

The introduction of Farm Circular Solution in Italy marks the first of a series of developments planned by Yanmar to refine the solution and expand its reach around Italy and Europe. This decentralised, local energy solution is key to achieving this goal.

The waste processing and gasification units are housed in standard shipping containers, enabling easy transportation between sites and close proximity to the farms being supplied with the energy and products. Future enhancements involve replacing the current generator, a modified Yanmar 4TNV98-IGECS diesel engine, with a Neotower 25.0 natural gas generator from Yanmar group company, RMB. The Neotower is already optimised for gas fuel generation and its use considerably simplifies development.

Beyond agriculture, there is the potential to adapt the concept for a ‘City Circular Solution’ in urban settings. This would apply the same principle as the farm solution, converting waste to energy to create a sustainable cycle within an urban environment.

The Farm Circular Solution is already bringing exciting changes to farming in Italy, and has the power to continue delivering long-term, sustainable benefits to Europe in the years to come.