News Release

Yanmar Introduces Its New Compact Micro Gas Cogeneration System

March 29, 2016

Yanmar Energy System Co., Ltd.

In collaboration with Tokyo Gas Co., Ltd., Osaka Gas Co.,Ltd., and Toho Gas Co., Ltd., Yanmar Energy System Co., Ltd. introduces the CP35D1 35 kW micro gas cogeneration system*1. All four companies will commence sale of the CP35D1 in Japan as of April 1.

Yanmar’s micro cogeneration systems up to the 100 kW range are well regarded due to the company’s years of experience as an engine manufacturer, for being built in Japan with a reputation of reliability, and for employing full functionality essential for systemization. This is further strengthened with competitive pricing and a compact unit size, optimized with comprehensive telematic serviceability for additional productivity.

Yanmar’s cogeneration systems use gas as the fuel source for electricity generation, and the resulting exhaust heat can then be utilized for additional energy purposes such as for the hot‐water supply. From the perspectives of CO2 reduction, less energy consumption during peak hours, and risk minimization, Yanmar’s cogeneration systems are the perfect choice for a wide range of facilities including hospitals, restaurants, factories and hotels.

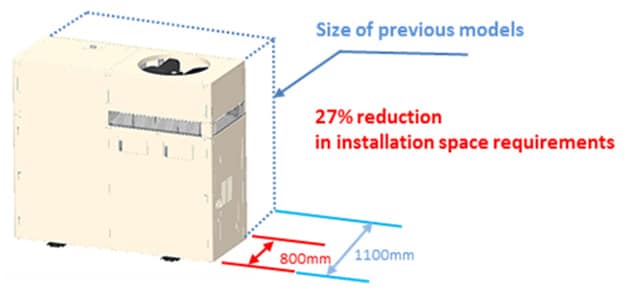

Combustion system optimization has led to a significant reduction in engine size, allowing for this 35 kW engine to be as compact as a 25 kW micro cogeneration engine would typically be — compared to previous models that’s a 27% decrease in space that the unit requires. This is further backed up by an industry-leading overall-efficiency*2 of 88%.

- *1Gas cogeneration systems use natural gas or biogas as the fuel source for electricity generation, and the resulting exhaust heat can then be utilized for additional energy purposes such as for the hot‐water supply. For establishments looking to satisfy both energy and hot water requirements, gas cogeneration systems are proven to be highly effective due to their low cost and fuel-efficient capabilities, further reinforced by their impressive overall-efficiency. (Large-size cogeneration: 2000 kW and above, mid-size cogeneration: 300-1999 kW, small-size cogeneration: less than 300 kW, micro cogeneration: in the small-size range, however less than 100 kW.)

- *2Overall-efficiency is factored as the amount of outputted energy compared to the amount of inputted energy. For cogeneration systems the electricity generated and the reusable energy derived from the exhaust heat make up the amount of energy output.

Key Features

1. Indoor Installation Enhancements

Reduction of Installation Space Requirements

By utilizing stoichiometric combustion all fuel is completely combusted, enabling this 35 kW cogeneration system to be reduced to the size of a 25 kW. The end result is a 27% decrease (a depth reduction of 300 mm) in the installation space required compared to previous 35 kW models.

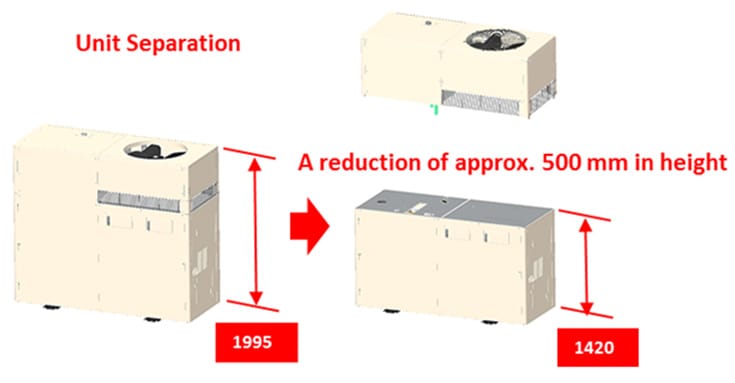

Maneuverability Improvements

Internal layout modifications allow for the top and bottom of the unit to be separated, enabling easier installation in tight quarters.

Water-cooled Availability

With conventional air cooled radiators built for the purpose of heat dissipation, a considerable effort was required in the duct installation process, putting restrictions on where they could be installed. Now, optionally for facilities in which a cooling system is already in place, the CP35D1 can be connected directly to the existing cooling system, utilizing cold water for cooling, thereby taking away the need for a built-in radiator. The end result is more options available for where to install the CP35D1.

2. Better Overall-Efficiency

Stoichiometric combustion benefits from having a higher exhaust temperature compared to other combustion systems. Now, with enhancements to the heat exchanger which recovers exhaust heat, in addition to improvements in pipe configuration and thickness, better heat exchange efficiency has been achieved, resulting in industry-leading overall-efficiency for micro cogeneration systems.

35 kW Micro Cogeneration Specifications

| Specification | New Products | Previous Models | |||

|---|---|---|---|---|---|

| CP35D1-TNJG Standard Spec*4 |

CP35D1Z-TNJG Spec for Power Outages*4 |

CP35VC-TN Standard Spec |

CP35VCZ-TN Spec for Power Outages |

||

| Rated Power(kW) | 35 | 35 | 35 | 35 | |

| Heat Recovery(kW) | 56.9 | 56.9 | 52.5 | 52.5 | |

| Heat Recovery Outlet Temperature(℃) |

80 (max 88℃) | 80 (max 88℃) | 80 (max 88℃) | 80 (Max 88℃) | |

| Efficiency | Overall Efficiency(%) | 88.0(87.0)*5 | 88.0(87.0)*5 | 85.0(84.0)*5 | 85.0(84.0)*5 |

| Generating Efficiency(%) | 33.5 | 33.5 | 34.0 | 34.0 | |

| Heat Recovery Ratio(%) | 54.5(53.5)*5 | 54.5(53.5)*5 | 51.0(50.0)*5 | 51.0(50.0)*5 | |

| Dimensions | Width(mm) | 2,000 | 2,000 | 2,000 | 2,000 |

| Depth(mm) | 800 | 800 | 1,100 | 1,100 | |

| Height(mm) | 1,995 | 1,995 | 2,000 | 2,000 | |

| Weight(kg) | 1,350 | 1,390 | 1,470 | 1,530 | |

| Combustion System | Stoichiometric | Stoichiometric | Lean-burn | Lean-burn | |

| Suggested Retail Price (excl. tax)(JPY) |

10,300,000 | 11,800,000 | 10,300,000 | 11,800,000 | |

- *4Both models are available without a radiator

- *5Numbers in brackets represent efficiency at a hot water temperature of 88°C

About Yanmar

With beginnings in Osaka, Japan in 1912, Yanmar was the first ever to succeed in making a compact diesel engine of a practical size in 1933. Moving on, with industrial diesel engines as the cornerstone of the enterprise, Yanmar has continued to expand its product range, services, and expertise to deliver total solutions as an industrial equipment manufacturer. As a provider of small and large-size engines, ag machines and facilities, construction equipment, energy systems, marine, machine tools, and components — Yanmar’s global business operations span seven domains.

On land, out at sea, and in the midst of the city, Yanmar’s Mission of “providing sustainable solutions focused on the challenges customers face, in food production and harnessing power, thereby enriching people’s lives for all our tomorrows,” stands testament to Yanmar’s determination in providing us with “a sustainable future.” For more information, visit Yanmar Co., Ltd. at its worldwide website at https://www.yanmar.com/global/about/.

Inquiries

Public Relations Group

Brand Communication Division, Yanmar

E-mail: koho@yanmar.com

- Note: Information contained in the news release is valid at the time of publication and may differ from the most recently available information.

Agriculture

Agriculture

Recreational Marine

Recreational Marine

Recreational Boat

Recreational Boat

Premium Cruiser

Premium Cruiser

Marine Equipment

Marine Equipment

Marine Commercial

Marine Commercial

Propulsion Engines (High Speed)

Propulsion Engines (High Speed)

Propulsion Engines (Medium Speed)

Propulsion Engines (Medium Speed)

Auxiliary Engines

Auxiliary Engines

SCR System

SCR System

Dual Fuel Engine

Dual Fuel Engine

Two-stage Turbocharging System

Two-stage Turbocharging System

Electric Propulsion System

Electric Propulsion System

Energy Systems

Energy Systems

Compact Equipment

Compact Equipment

Industrial Engine

Industrial Engine

Power Generation

Power Generation

Compact Power Products

Compact Power Products